Roofing work is inherently hazardous, with risks such as falls from heights, electrical shocks, slips, trips, and falls, crushing injuries from heavy equipment and materials, exposure to hazardous substances, and weather-related dangers like lightning and strong winds. Understanding these risks is essential for implementing effective safety measures.

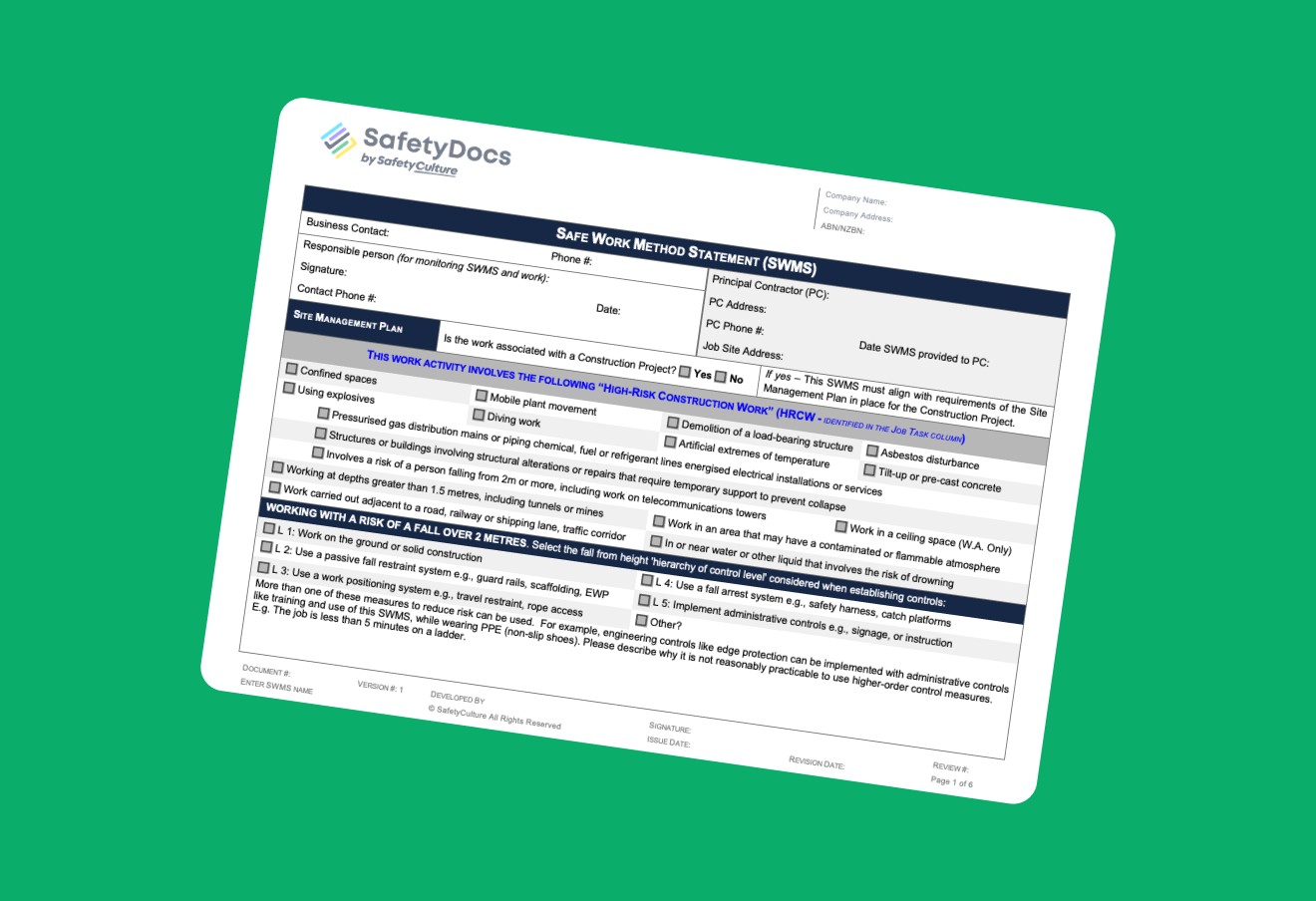

With our Roofing SWMS, you can confidently tackle these challenges while staying compliant with WHS regulations. Our comprehensive templates provide step-by-step guidance, breaking down tasks into clear job steps, helping teams identify risks and implement effective controls, ensuring safer and more efficient operations on every job.