1. Reduce Workplace Risks

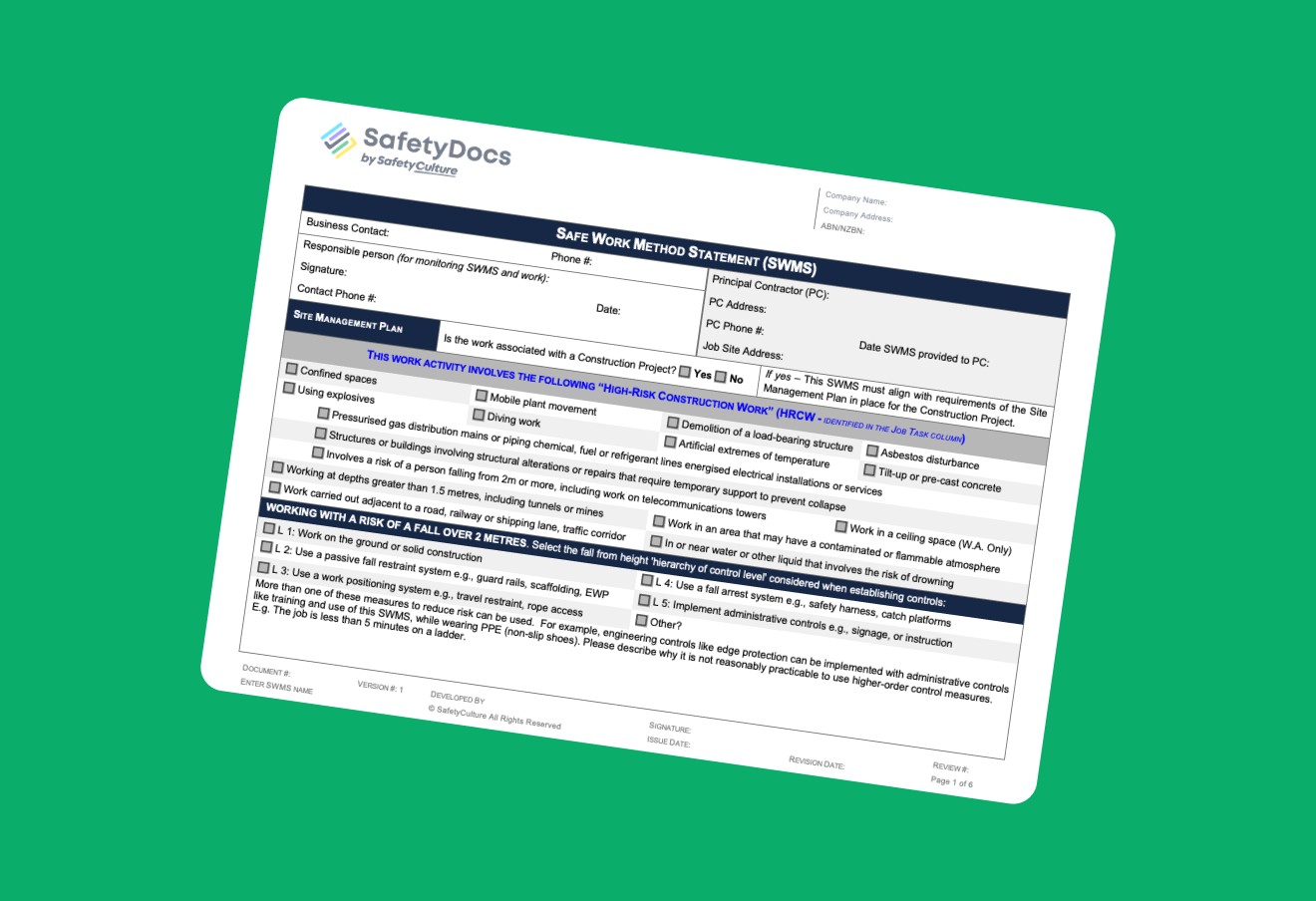

Plastering tasks often involve working at heights, handling hazardous materials, or using specialised equipment. Our Plastering SWMS outline safe work practices for controlling risks, so teams can stay protected.

2. Simplify WHS Compliance

Our templates address industry-specific hazards and align with WHS legislation, making compliance simple and stress-free.

3. Work Smarter, Not Harder

Pre-written SWMS save time while providing clear safety protocols, enabling teams to work efficiently and confidently. These user-friendly documents are designed with simplicity and ease of use in mind, ensuring that even complex safety information is easy to understand and follow.