Support Team Notice – Our support team will be unavailable from 25 Dec – 05 Jan. You can still order documents online and they will be emailed automatically with their download link.

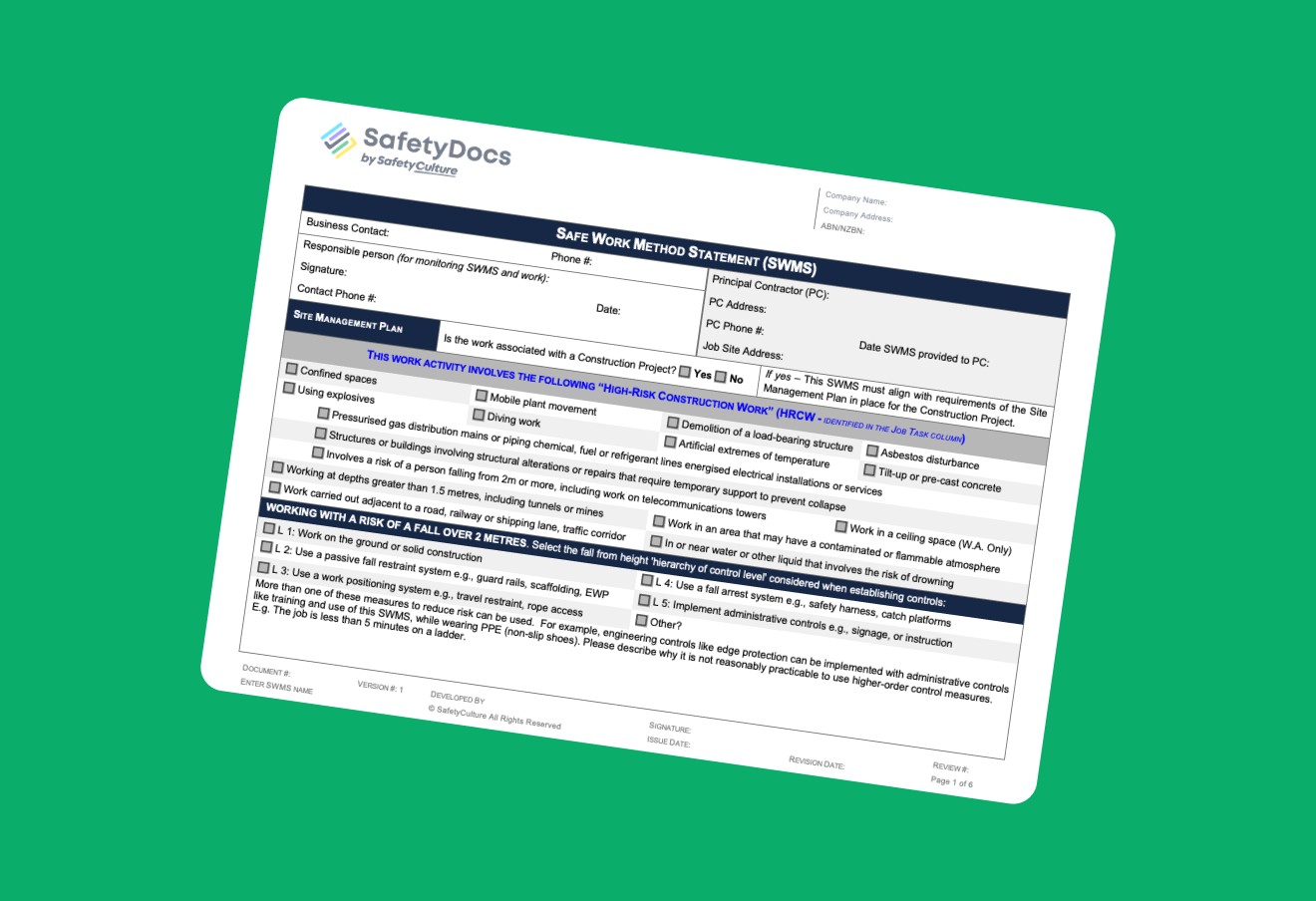

Explore our Crane & Lifting Equipment Safe Work Method Statements (SWMS), featuring safety protocols for diverse crane types and lifting devices. Tailored to enhance safety in lifting operations, these SWMS ensure proper handling, operation, and maintenance of cranes and equipment, mitigating risks and promoting compliance with industry standards. Essential for operators and site managers, they provide a foundation for safe and efficient lifting practices.

Need help finding the right SWMS?

Add Your Own Logo

Only $14.95 Per Cart!Only $14.95 Per Cart!

With this powerful tool, you can add your logo, business name, address and ABN to all of the required fields within your documents for one low fee per cart - not per document. You will then receive your branded documents shortly after payment. Simply add at the cart!

Crane & Lifting Equipment SWMS Templates

Managing crane and lifting operations involves unique challenges and risks. Our Crane & Lifting Equipment Safe Work Method Statements (SWMS) provide clear, actionable guidance to help businesses prioritise safety, minimise hazards, and meet regulatory requirements. From mobile cranes to tower cranes, these templates cover essential tasks with step-by-step safety procedures designed to keep your team secure and your projects on track.

Control Measures and SWMS

Implementing control measures and SWMS is essential for the safe use of lifting equipment. Control measures may include the use of personal protective equipment (PPE), proper lifting techniques, and the establishment of exclusion zones to prevent unauthorised access to the lifting area. Safe Work Method Statements should be developed for each lifting operation, detailing the steps required to ensure a safe and efficient lift. These SWMS must be communicated to all personnel involved in the lifting operation, and regular training should be provided to ensure everyone understands their roles and responsibilities. By adhering to these guidelines, workplaces can significantly reduce the risks associated with lifting activities.

Why Use Crane & Lifting Equipment SWMS?

1. Stay Ahead of Risks

Crane and lifting operations pose significant hazards, from load mismanagement to equipment malfunctions. SWMS help identify risks early, providing clear protocols to prevent accidents and protect workers. They help workers stay safe by providing clear guidelines and precautions to mitigate potential hazards associated with lifting heavy materials.

2. Achieve WHS Compliance with Ease

Our templates are built to align with Australian WHS regulations. By using our SWMS, businesses can streamline compliance and confidently address safety obligations.

3. Simplify Complex Tasks

Whether working with a mobile crane, gantry crane, or personnel hoist, these SWMS break down intricate processes into manageable, safety-focused steps.

Key Features of Our Crane & Lifting Equipment SWMS

- Wide Task Coverage: Includes detailed templates for operations such as truck-mounted cranes, self-erecting cranes, tower cranes, and workbox use. Each template is tailored to specific equipment and job roles, including dogmen and hoist operators.

- Customisable for Every Project: Adapt templates to suit your site and project requirements. Editable fields ensure your safety documentation meets the unique demands of each job.

- Instant Digital Access: Download your SWMS instantly after purchase. Start implementing safety measures without delay.

- Regulatory Compliance: Each template reflects current Australian WHS standards, helping you stay ahead of evolving safety requirements.

Benefits of Implementing Crane & Lifting Equipment SWMS

1. Protect Workers and Equipment

Well-documented safety practices reduce risks, safeguard lives, and extend the lifespan of equipment.

2. Enhance Efficiency and Confidence

Teams equipped with clear safety protocols can perform tasks with greater precision, avoiding delays caused by accidents or unclear processes.

3. Strengthen Your Safety Culture

Using SWMS demonstrates a strong commitment to workplace safety, building trust among employees and stakeholders.

Who Needs Crane & Lifting Equipment SWMS?

These SWMS are perfect for:

- Construction Companies: Handling projects with heavy lifting requirements, such as high-rise developments and infrastructure projects.

- Logistics and Transport Providers: Using truck-mounted cranes, gantry cranes, or personnel hoists to move heavy materials safely.

- Independent Contractors: Performing tasks like tower crane assembly, mini crane operation, or workbox lifting.

- Warehouse and Manufacturing Operators: Managing overhead cranes or other lifting equipment as part of daily operations.

Empower your business with comprehensive, easy-to-use safety solutions. Our Crane & Lifting Equipment SWMS Templates help you protect your workforce, meet compliance standards, and keep projects running smoothly.