Worker fatalities in Australia have exhibited a notable decrease over the years. The fatality rate per worker has nearly halved from 2.98 in 2004 to 1.43 in 2022. Despite these advancements in enhancing work health and safety standards, it is crucial to note that every work-related fatality is a tragedy. The ongoing need for continued efforts to ensure workplace electrical safety and reduce fatalities like electrical injuries and death is essential.

Electrical emergency preparedness is critical to workplace safety, especially for contractors and trades workers. This guide provides valuable information and resources to help contractors and tradespeople prepare for electrical emergencies.

Types of Electrical Emergencies

Contractors handle client tasks, including construction, electrical work, plumbing, painting, and landscaping. Tradespeople, or merchants, are skilled workers in trades like electricians, plumbers, carpenters, HVAC technicians, welders, and mechanics. Both are at risk of encountering electrical emergencies while on the job.

In a recent event in Queensland in November 2023, a roofer working on the roof of a single-story house being built suffered an injury. The incident occurred when a metal roof truss contacted an electrical conductor during relocation. This occurrence falls under the Serious Electrical Incidents (SEI) category defined by the Electrical Safety Act of 2002 (ES Act). Such incidents highlight the importance of preparedness for electrical emergencies.

This incident is just one example of the many electrical emergencies on a job site. These emergencies can range from minor shocks and burns to more severe incidents such as house fires or electrocutions.

Electrical Shock

Contact with live electrical wires or equipment can result in electric shock, which can cause burns, cardiac arrest, or even death.

Power Outages

Unexpected power outages can arise from various factors, including extreme weather conditions, equipment malfunctions, or grid surges. While not always life-threatening, power outages can disrupt daily activities and compromise electrical safety, especially in critical environments like hospitals or industrial facilities.

Electrical Storm Damage

Lightning strikes or power surges during storms can cause extensive damage to electrical systems, leading to fires, power outages, or equipment failure.

Electrical Equipment Malfunction

Faulty or poorly maintained electrical equipment can malfunction, leading to sparks, smoke, or even explosions. This can happen in residential, commercial, or industrial settings and requires immediate attention to prevent further damage or injury.

Downed Power Lines

Fallen power lines pose a significant danger, whether due to storms, accidents, or other causes. They can still be live and carry high voltages, making them extremely hazardous.

Electrical Substation Emergencies

Issues at electrical substations, such as equipment failures, transformer explosions, or fires, can disrupt power distribution on a large scale and require prompt intervention by trained professionals.

Arc Flashes and Arc Blasts

These occur when electrical current arcs through the air, generating intense heat and pressure. Arc flashes and blasts can cause severe burns, blast injuries, and damage to surrounding equipment and structures.

Carbon Monoxide Poisoning

Malfunctioning electrical appliances, such as generators or heating systems, can produce carbon monoxide (CO) gas, which is odourless and colourless but highly toxic.

Electrical Accidents in Water

Electrical appliances or equipment near water sources, such as swimming pools, bathrooms, or flooded areas, can pose a significant electrocution risk.

Common Causes of Electrical Emergencies

Understanding the root causes of electrical emergencies is essential for prevention. The abovementioned emergencies are caused by various factors, including:

- Overloaded circuits: When too many electrical appliances or equipment are plugged into the same circuit, it can overload the system and cause a fire.

- Old or damaged wiring: Worn-out or damaged wiring can cause short circuits, leading to electrical fires.

- Wet conditions: Water is a conductor of electricity, and when it comes into contact with an electrical source, it can lead to electrocution.

- Faulty wiring or equipment: Faulty wiring or equipment can cause electrical fires and other emergencies.

- Improper use of extension cords: Using extension cords for long periods or connecting multiple devices to one cord can overload the system and potentially cause a fire.

- Lack of maintenance: Failure to regularly inspect and maintain electrical systems can lead to malfunctions and emergencies.

- Overhead and underground power lines: Contact with overhead or underground can cause electrocution and electrical fires.

- Flammable materials: Placing flammable materials near electrical sources can quickly lead to a fire in case of a spark or short circuit.

- Inadequate isolation and lockout/tag-out procedures: Failing to isolate and secure electrical systems properly during maintenance or repair can lead to severe accidents.

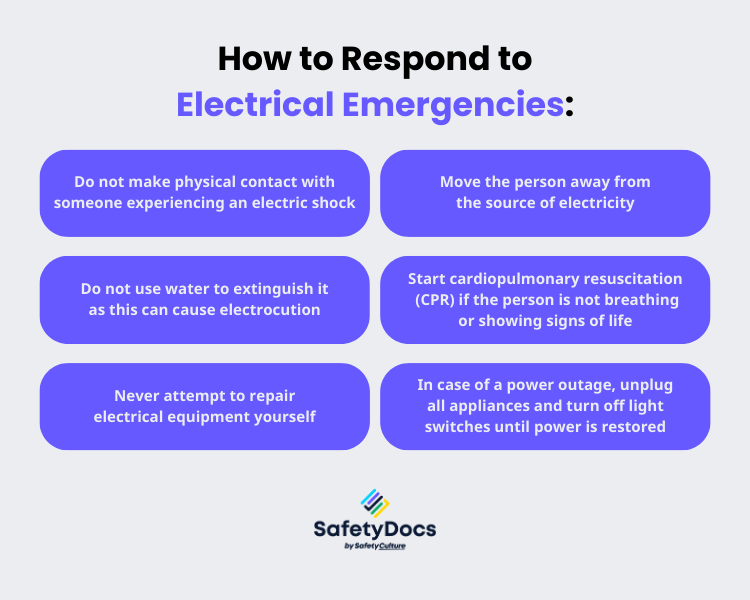

How to Respond to Electrical Emergencies

- Do not make physical contact with someone experiencing an electric shock. Instead, turn off the power source using a circuit breaker or unplug the appliance if it is safe.

- If you cannot safely turn off the power, try to move the person away from the source of electricity using a non-conductive object such as a wooden broom handle. Call 000 and seek medical attention immediately.

- In case of an electrical fire, do not use water to extinguish it as this can cause electrocution. Instead, use a Class C fire extinguisher specifically designed for electrical fires or smother the fire with a heavy blanket or coat.

- Never attempt to repair electrical equipment yourself. Always hire a licensed electrician for repairs or installations to avoid accidents.

- Start cardiopulmonary resuscitation (CPR) if the person is not breathing or showing signs of life. Begin with chest compressions and follow the instructions given by emergency services until medical professionals arrive.

- In case of a power outage, unplug all appliances and turn off light switches until power is restored. This will prevent a surge of electricity when power returns, which can cause damage to appliances and potentially start fires.

Preventing Electrical Emergencies

It is not enough that you know what to do in electrical emergencies. It is equally important to understand how to prevent them from happening in the first place. Here are ways to prevent electrical emergencies:

1. Provide Essential Electrical Safety Equipment

Personal Protective Equipment (PPE)

Contractors and tradespeople should always wear appropriate PPE when working with or around electrical systems. This includes insulated gloves, safety goggles, and non-conductive footwear to minimise the risk of electrical shock.

Emergency Response Kits

Emergency response kits should be readily available on worksites and equipped with essential tools such as voltage testers, insulated tools, and fire extinguishers. These kits enable prompt and effective responses to electrical emergencies.

2. Establish Emergency Procedures and Protocols

In an electrical emergency, it is crucial to follow established procedures promptly. This may include:

Designated Emergency Response Team

It is essential to have a designated team responsible for responding to electrical emergencies. They should be trained in handling different electrical issues and incidents and equipped with the necessary knowledge and tools.

Communication Protocols

Proper communication is crucial during an electrical emergency. All workers on site must know who to contact in case of an incident, how to communicate effectively, and when to call for professional assistance.

3. Provide Training and Education for Electrical Emergencies

First Aid for Electrical Shock

Knowing how to administer first aid for electrical shock incidents can be life-saving. Immediate actions for electric shock may include shutting off power, performing CPR if necessary, and seeking medical attention for the injured individual.

CPR Training

Contractors and tradespeople should undergo CPR training to respond to cardiac emergencies resulting from electrical shocks or other incidents. Timely administration of CPR can greatly enhance the chance of the victim's survival.

Fire Extinguisher Training

All workers should receive training in properly using fire extinguishers to extinguish small fires safely. Understanding the different types of extinguishers and their applications is essential for effective fire suppression.

4. Secure the Worksite

Lockout/Tagout Procedures

Lockout/tagout procedures are essential for preventing unexpected startup of equipment or machinery during power outages. It means securing all energy sources to avoid accidental re-energisation, helping to keep workers safe.

Fire Suppression Equipment

Having appropriate fire suppression equipment on-site, such as fire extinguishers and sprinkler systems, can help contain fires and limit damage during emergencies. Employees need to be trained in how to use this equipment effectively.

Emergency Shut-off Valves

Ensure all emergency shut-off valves are easily accessible and labelled clearly in case of a power outage. These valves will allow for quick and safe shutdown of gas, electricity, water, or other hazardous materials in an emergency.

5. Conduct Regular Maintenance

Regularly scheduled maintenance and inspections of all equipment and machinery can help identify potential risks or malfunctions before they become a problem during a power outage. Ensure that all manufacturers' recommended maintenance schedules are followed and keep records of these activities.

Inspections and Testing

Routine inspections and testing of electrical systems help ensure their integrity and functionality. Identifying and addressing deficiencies promptly can mitigate risks and prolong the lifespan of electrical infrastructures.

6. Implement Post-Emergency Assessment and Documentation

Examples of necessary documentation in preventing electrical emergencies include:

- Detailed Incident Records: Maintaining detailed records of electrical incidents, actions taken, and outcomes is crucial for learning from past emergencies and improving electrical safety rules.

- Safe Operating Procedures (SOPs): detailed instructions for adequately operating electrical equipment, including intended use, safety procedures, hazard information, and recommended accessories, are vital for preventing misuse and accidents.

- Inspection Reports: Regular electrical system inspections by qualified personnel to spot electrical hazards, take immediate action to reduce risks, and ensure safety compliance are crucial for preventing emergencies.

- Training Records: Keeping records of employee and household member training on electrical safety, including hazard identification, safe device usage, and emergency response procedures, is crucial for reducing the risk of accidents.

7. Develop an Electrical Emergency Response Plan

An Electrical Emergency Response Plan is a comprehensive strategy designed to guide contractors, tradespeople, and other personnel in effectively responding to electrical emergencies. It includes steps for assessing the situation, ensuring the safety of individuals, and minimising property damage. Additionally, the plan may detail communication protocols, evacuation procedures, and personnel roles and responsibilities during emergencies.

Additionally, investing in a robust plan is crucial not only for the safety of employees but also demonstrates a commitment to compliance with health and safety regulations. Employers must ensure a safe work environment for their employees as a legal responsibility, which encompasses providing proper training and implementing emergency response protocols.

Simplify Electrical Emergency Planning With SafetyDocs

Your company can be better prepared for any potential electrical emergencies with SafetyDocs by SafetyCulture. The right tools for streamlined documentation and planning can make all the difference in preventing or minimising property damage, injuries, and even fatalities.

SafetyDocs offers customisable templates for electrical safety compliant with relevant regulations and standards. These templates allow you to tailor your plan to suit your workplace needs and avoid electrical hazards. You can start with the planning with the following templates:

- Electrical Emergency Response Plan

- Electrician's Safe Work Method Statements Pack

- Electrical Management Plans

- Electrical-HVAC-Solar Safety Packages

Don't let ignorance or lack of preparation put your workplace at risk. Contact us and download our customisable electrical safety documents template.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article