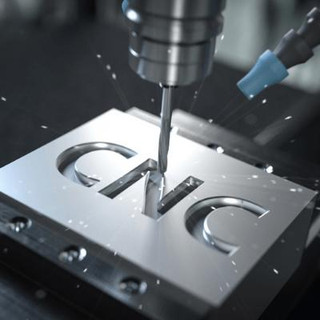

CNC Router Safe Operating Procedure

- Instant Document Delivery via Email.

- Add to your existing management system.

- Can assist in ensuring workers are adequately trained.

- Customisation instructions provided.

- Microsoft Word Format (Fully editable).

- Only pay once (no subscriptions required).

CNC Router Safe Operating Procedure (SOP)

The CNC Router Safe Operating Procedure (SOP) is designed to help businesses implement safe practices when using CNC Routers.

Contents

- Hazards: Identifies potential hazards including noise, electricity, moving parts, dust, laser beams, manual handling, and poor housekeeping.

- PPE: Lists personal protective equipment required to operate a CNC Router safely.

- Pre-operational Inspection: Checklist so all components are in optimal condition before use, including alignment checks and tool inspections.

- Precautions: Identifies essential training and competency requirements for operators, covering workplace induction, safe operating procedures, and first aid.

- Maintenance: Summarises the importance of LOTO procedures and maintaining a log of service and repairs.

- Operation: Detailed instructions for safe operation, including material loading, machine settings, and emergency stop functions.

- Maintenance/Cleaning: Guidelines for cleaning and maintaining the CNC Router, including the use of appropriate PPE during these tasks.

- Hazard Checklist: A comprehensive checklist so all safety measures are in place, covering risk assessments, guard conditions, and control accessibility.

SOP Training Quiz

The CNC Router Safe Operating Procedure incorporates a training quiz designed to reinforce learning and assess worker comprehension:

- Interactive Learning: The quiz provides an engaging tool to test workers' understanding of the SOP.

- Assessment Format: Featuring multiple-choice and true/false questions, the quiz evaluates knowledge effectively, with answers to facilitate learning.

Equip your team with the knowledge to operate CNC Routers safely and efficiently.

- Instant Document Delivery via Email.

- Add to your existing management system.

- Can assist in ensuring workers are adequately trained.

- Customisation instructions provided.

- Microsoft Word Format (Fully editable).

- Only pay once (no subscriptions required).

CNC Router Safe Operating Procedure (SOP)

The CNC Router Safe Operating Procedure (SOP) is designed to help businesses implement safe practices when using CNC Routers.

Contents

- Hazards: Identifies potential hazards including noise, electricity, moving parts, dust, laser beams, manual handling, and poor housekeeping.

- PPE: Lists personal protective equipment required to operate a CNC Router safely.

- Pre-operational Inspection: Checklist so all components are in optimal condition before use, including alignment checks and tool inspections.

- Precautions: Identifies essential training and competency requirements for operators, covering workplace induction, safe operating procedures, and first aid.

- Maintenance: Summarises the importance of LOTO procedures and maintaining a log of service and repairs.

- Operation: Detailed instructions for safe operation, including material loading, machine settings, and emergency stop functions.

- Maintenance/Cleaning: Guidelines for cleaning and maintaining the CNC Router, including the use of appropriate PPE during these tasks.

- Hazard Checklist: A comprehensive checklist so all safety measures are in place, covering risk assessments, guard conditions, and control accessibility.

SOP Training Quiz

The CNC Router Safe Operating Procedure incorporates a training quiz designed to reinforce learning and assess worker comprehension:

- Interactive Learning: The quiz provides an engaging tool to test workers' understanding of the SOP.

- Assessment Format: Featuring multiple-choice and true/false questions, the quiz evaluates knowledge effectively, with answers to facilitate learning.

Equip your team with the knowledge to operate CNC Routers safely and efficiently.