Ergonomics is often misunderstood as only relevant to office settings, focusing on comfortable chairs and desk heights. However, it plays a critical role in physically demanding industries like logistics.

In logistics, workers frequently handle manual tasks such as lifting, lowering, pushing, pulling, carrying, or moving objects. These activities contribute to body stress, the leading cause of injuries in the road transport industry. In fact, body stress accounts for 43% of Australia's serious workers' compensation claims.

Let's dive deeper into the ergonomic hazards in logistics and how they impact workers and operations.

What is Ergonomics in Logistics?

Ergonomics in logistics refers to applying ergonomic principles and practices within the industry to improve workers' ergonomics safety and efficiency. It involves designing tasks, workspaces, and equipment to fit workers' needs and capabilities. Ergonomics in logistics aims to create a safer workplace by reducing hazards and other injuries.

Ergonomic Hazards in Logistics

Ergonomic hazards in logistics are risks from poorly designed tasks, workspaces, or equipment. These can cause physical stress and injuries, affecting employees' health and operational efficiency. Common ergonomic hazards in the logistics industry include:

Manual Handling Tasks

- Lifting and Lowering: Repeatedly lifting or lowering heavy objects, such as loading and unloading trucks, stacking pallets, and moving inventory in a warehouse, can strain the back, shoulders, and knees.

- Pushing and Pulling: Moving heavy objects on wheels, such as trolleys or carts, can cause strain on the arms and shoulders.

- Carrying: Holding heavy objects for extended periods can cause strain on the arms, shoulders, and back.

- Repetitive Motions: Repeating the same movements over time, such as picking and packing items or scanning barcodes, can lead to strain and fatigue.

Awkward Postures

Logistics workers often have to work in tight spaces or reach for objects in hard-to-reach areas. This can force them into awkward postures, leading to discomfort and pain. Some common examples are:

- Twisting while lifting heavy objects in confined spaces like a truck or shipping container.

- Reaching upwards or sideways for inventory on high shelves in a warehouse.

- Prolonged, static postures include sitting in a truck cab for long hours without breaks.

- Driving long distances in a fixed position causes strain on the back and legs.

Heavy Lifting

Manual handling tasks involving heavy loads are among the leading causes of injury and time off work in logistics. Workers who don't use proper lifting techniques or receive insufficient training are at risk of developing strains, sprains, and other musculoskeletal injuries.

Inadequate Workspace Design

Workplace design is crucial to prevent muscle injuries. Poor setups, such as fixed seats or workstations requiring frequent reaching or twisting, can harm workers' muscles.

The Impact on Workers and Operations

The consequences of ignoring ergonomic hazards and human factors in logistics can be severe, affecting both workers and operations.

Impact on Workers

1. Musculoskeletal Disorders (MSDs)

Musculoskeletal disorders (MSDs) are injuries or disorders of the muscles, tendons, ligaments, joints, nerves, and blood vessels caused by work-related activities. In logistics, MSDs often manifest as strains, sprains, lower back pain, and carpal tunnel syndrome.

These conditions can cause severe discomfort and make it challenging for workers to perform their duties efficiently. They may also lead to long-term physical disabilities if left untreated.

2. Reduced Productivity

Poor ergonomics can increase fatigue, reducing workers' ability to perform tasks efficiently. Injured or fatigued workers may take longer to complete tasks, decreasing productivity.

3. Increased Absenteeism

Workers suffering from ergonomic work health-related injuries are more likely to take time off, leading to higher absenteeism rates. Chronic injuries and discomfort may also increase turnover rates as workers seek less physically demanding jobs.

4. Mental Health

Physical pain and discomfort can contribute to stress and mental health issues. Workers dealing with chronic pain may experience increased levels of stress and a decreased quality of life.

Impact on Operations

- Operational Efficiency

- Decreased Output: Workers' injuries and fatigue can slow operations, resulting in delays, backlogs, and missed delivery deadlines.

- Errors and Accidents: Fatigued workers are more prone to mistakes. Handling heavy machinery or driving long distances can lead to serious accidents and property damage.

- Financial Costs

- Healthcare Expenses: Companies may face increased healthcare costs due to treatment for work-related injuries.

- Compensation Claims: Ergonomic injuries can increase workers' compensation claims and insurance premiums. As mentioned above, body stress accounts for many serious claims in the road transport industry.

- Workforce Management:

- Training and Recruitment: Higher turnover rates necessitate continuous recruitment and training of new employees, which can be costly and time-consuming.

- Temporary Staffing: To cover for injured workers, companies might need to hire temporary staff, which can disrupt workflow and increase operational costs.

- Reputation and Compliance:

- Regulatory Compliance: Failure to address ergonomic hazards can lead to non-compliance with occupational health and safety regulations. Employers are required to identify, assess, and control ergonomic hazards and risks.

- Company Reputation: A company known for poor working conditions and high injury rates may struggle to attract and retain talent, which can impact its reputation and profitability.

Ergonomic Solutions for Logistics

Manual Handling Training

One of the most effective ways safety representatives prevent injuries in logistics is through manual handling training. This training should be tailored to workers' tasks rather than providing generic lifting advice.

Key Components of Effective Manual Handling Training

- Ergonomic Assessments: Conduct a job safety analysis to identify specific manual handling challenges. Tailor the training program to address the needs and risks identified in the job analysis.

- Instruction on Proper Techniques:

- Lifting Techniques: Teach safe lifting techniques, including bending at the knees, keeping the back straight, and holding items close to the body.

- Carrying Methods: Instruct how to distribute weight evenly and use both hands to carry loads to avoid physical strain.

- Pushing and Pulling: Provide guidelines on the safest ways to push and pull heavy objects, emphasising the use of body weight and proper posture.

- Use of Mechanical Aids: Educate workers on correctly using mechanical aids such as pallet jacks, forklifts, and conveyor systems to reduce manual handling requirements.

- Ergonomic Principles: Focus on ergonomic principles, such as maintaining neutral postures, avoiding twisting movements, and taking regular breaks to stretch and rest. Modifications to the work environment, such as adjustable equipment and clear pathways, should also be addressed.

- Practical Exercises:

- Hands-On Practice: Incorporate practical exercises where workers can practise proper techniques under the supervision of trained instructors.

- Feedback: Provide immediate feedback to reinforce correct practices and correct improper techniques.

- Ongoing Evaluation and Refresher Courses: Regularly evaluate manual handling practices to ensure continued compliance and effectiveness. Offer periodic refresher courses to reinforce good practices and update workers on any new techniques or equipment.

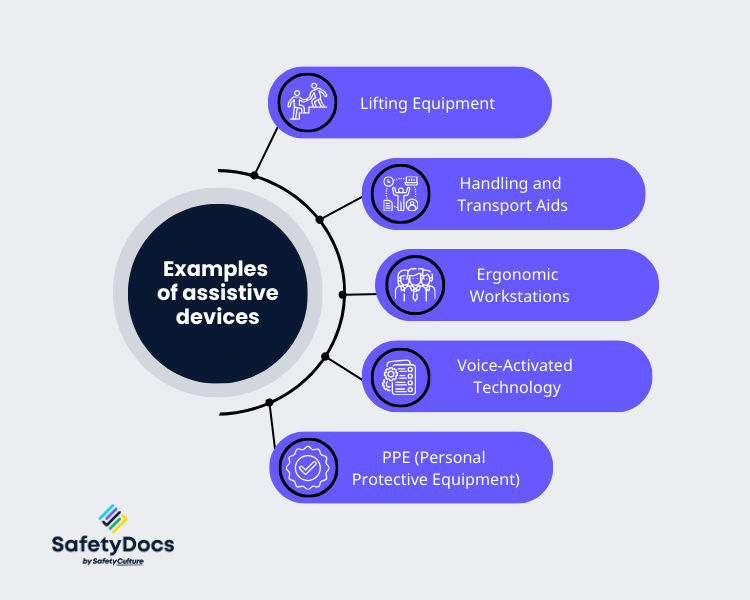

Assistive Devices

Logistics uses assistive devices, such as lifting equipment, handling and transport aids, and ergonomic workstations. These devices can reduce the need for manual handling and make tasks less physically demanding.

Examples of Assistive Devices

Lifting Equipment:

- Forklifts: Used to lift and transport heavy loads efficiently.

- Pallet Jacks: An alternative to manual lifting, they allow workers to quickly move pallets and other heavy items.

Handling and Transport Aids:

- Conveyor Systems: Reduce the need for manual handling of heavy or awkward items by automatically moving them along a designated path.

- Trolleys and Carts: These can transport multiple items simultaneously, reducing the required trips.

Ergonomic Workstations:

- Height-Adjustable Desks: These allow workers to adjust the height of their workstations, reducing strain on back and neck muscles.

- Anti-Fatigue Mats: Provide cushioning and support for workers standing in one spot for long periods.

Voice-Activated Technology:

- Speech Recognition Software: Enables workers to input data and commands using their voice, reducing the need for typing or manual data entry.

- Hands-free headsets: Allow workers to communicate without using their hands, facilitating tasks such as picking and packing orders while staying connected with colleagues or supervisors.

PPE (Personal Protective Equipment): In situations where manual handling cannot be avoided, employers should provide PPE such as back belts, knee pads, and gloves to reduce strain on specific body parts.

Warehouse Design

Optimising warehouse design is another critical aspect of improving logistics ergonomics safety. A well-designed warehouse reduces the need for workers to reach, twist, or bend awkwardly. It also promotes efficient workflow, reducing strain and fatigue.

Key Considerations for Warehouse Design

- Layout: The layout should minimise the need for manual handling by keeping frequently used items close to workers.

- Storage Systems: Use adjustable shelving and storage systems to reduce reaching and bending.

- Clear Pathways: Keep pathways clear of obstacles to prevent trips, falls, and other injuries.

- Lighting: Proper lighting is essential in avoiding errors and accidents caused by poor visibility.

- Temperature Control: Maintain a comfortable temperature in the warehouse to reduce physical stress on workers' bodies.

- Ergonomic Workstations: Provide ergonomic workstations with adjustable heights and adequate space for tasks such as packing,

Job Rotation

Job rotation involves the systematic movement of workers through different tasks or roles within a workday or workweek. This approach to workplace adjustments helps mitigate the risks associated with repetitive strain injuries and muscle fatigue while promoting overall worker well-being and productivity.

When Job Rotation is Necessary

- Repetitive Tasks: Jobs that involve high repetition, such as picking and packing, are suitable for job rotation.

- Heavy Lifting: Heavy lifting workers should rotate with lighter tasks to avoid overexertion.

- Sedentary Tasks: Workers who spend long periods sitting at a workstation can benefit from rotating into more active roles throughout the day.

- Variety in Work Environments: Job rotation can also include moving workers between warehouse areas or indoor and outdoor work environments.

Driver Ergonomics

Driver ergonomics refers to the design and arrangement of a vehicle's interior to optimise the comfort, safety, and efficiency of drivers. This is especially critical in the logistics industry, where drivers often spend long hours behind the wheel, handling various vehicles like trucks, forklifts, and delivery vans.

Key Elements

- Seat Design and Adjustment

- Seats should have ample lumbar support, cushioning, and adjustability to fit different body types and sizes.

- The seat should be adjustable regarding height, tilt, and distance from the steering wheel and pedals.

- Steering Wheel and Controls

- Steering wheels should be adjustable for both tilt and telescopic movement, allowing drivers to position it comfortably relative to their body.

- Controls for lights, indicators, and other functions should be within easy reach to minimise stretching and awkward postures.

- Pedal Placement

- The pedals should be positioned so drivers can operate them without stretching or straining their legs.

- Pedals should have an anti-slip surface to ensure safe operation.

- Visibility and Mirrors

- Ensure drivers have a clear line of sight to the road and dashboard instruments.

- Side and rearview mirrors should be easily adjustable to minimise blind spots and reduce the need for excessive head and body movement.

- Cabin Environment

- Effective air conditioning and heating systems to maintain a comfortable cabin temperature.

- Soundproofing measures to reduce cabin noise, helping to reduce stress and fatigue.

- Access to Tools and Devices

- When holding the steering wheel, encourage drivers to maintain a straight back, relaxed shoulders, and elbows at a 90-degree angle.

- Instruments and controls should be laid out logically and user-friendly.

- Integration of hands-free communication devices and GPS systems to allow drivers to stay connected without compromising safety.

- Posture Support

- When holding the steering wheel, encourage drivers to maintain a straight back, relaxed shoulders, and elbows at a 90-degree angle.

- Drivers should adjust their seating periodically to prevent stiffness and maintain circulation.

Mitigate Ergonomics Hazards With SafetyDocs

Incorporating ergonomic principles in the workplace starts with using the right tools in the solutions. With proper tools and guidance, employers may be able to identify or rectify risks associated with workplace ergonomics. SafetyDocs by SafetyCulture provides workplaces with comprehensive safety management solutions for proper ergonomics. We offer customisable documents and checklists to identify ergonomic hazards, assess risks, and implement effective measures.

From warehouse design to health and safety issues to manual handling to driver ergonomics, SafetyDocs can help create a safer and more ergonomic workplace. Start with the following documents:

- Manual Handling Risk Assessment Form

- Manual Handling Management Plan

- Manual Handling Safe Operating Procedure

- Driver Posture & Responsibilities Safe Operating Procedure

Don't let ergonomic safety hazards harm your workers' health and productivity—start implementing effective solutions today with SafetyDocs. Contact us for more information about our products.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article