Machinery guarding plays a crucial role in ensuring the safety and well-being of workers in mechanical plants. It involves the implementation of physical barriers, devices, and safety measures to protect individuals from the hazards associated with machinery and equipment. Adhering to local safety regulations and standards that mandate machinery guarding safety is paramount. Let's delve deeper into why machinery guarding is significant in mechanical plant.

What is Machine Guarding?

Machine guarding refers to the measures taken to protect workers from hazards created during machines' normal operation, servicing, and maintenance. Machine guarding safeguards employees from workplace hazards, including rotating parts, crushing or shearing points, and sparks.

Guarding methods, such as barrier guards, two-hand tripping devices and electronic safety devices, among others, are put in place to prevent accidents. Whenever feasible, guards must be affixed to the machine, securing them elsewhere when attachment to the engine is impossible. It's critical that the guard avoids creating any hazard, thereby fulfilling its intended safety purpose.

Machine guarding is a common safety practice used in workplaces where machines are present. Here are some examples:

- Construction sites

- Warehouses

- Agricultural settings, such as crop harvesting and livestock care

- Laboratories, such as medical and veterinary

- Woodworking shops

- Metalworking shops

- Automotive repair shops

- Mechanical plants

Machines in these settings can cause minor injuries like cuts or burns to serious injuries such as fracturing, laceration, crushing, or amputation.

Machine Guarding in Mechanical Plant

Mechanical plant, otherwise recognised as industrial plants or physical plants, are the vital infrastructures that support the operation and maintenance of various facilities. The term "mechanical plant" can also refer to a plant designed and constructed with a series of steel or concrete basins using pumps, pipes, and other equipment to perform a specific function. They can include a wide range of facilities, such as:

- Power plants, including nuclear power plants, use a series of steel or concrete basins, pumps, pipes, and other equipment to generate electricity

- Data centres, which require a mechanical plant to support and maintain the facility, including heating, cooling, and electrical hubs

- Manufacturing plant, which use a variety of machinery and equipment, such as excavators, cranes, and dumpers, to produce goods

- Packaging industries, which use material handling equipment, such as conveyor belts, to move products through the manufacturing process and packaging equipment machinery to pack the products

Importance

1. Protection against Hazards

Machinery in mechanical plant can pose numerous hazards, including rotating parts, sharp edges, and moving components. Proper machinery guarding prevents workers from directly contacting these hazardous elements. Using guards also eliminates the potential for any human error that could lead to accidents. Here are some common hazards in mechanical plants that require machine guarding:

- Moving machine parts, such as rotating, reciprocating, transversing parts, and flying chips or sparks, which can cause severe workplace injuries.

- Ingoing nip points, which can cause minor abrasions, burns, or cuts, and more severe injuries such as lacerations, crushing, fractures, or even amputation

- Falling objects, such as tools, a machine part, or materials, that can cause workers to slip and fall

- Electric shock, which can cause severe injuries due to electric current passing through the bod

- Slip, trip, and fall hazards in the areas surrounding machines

- Loose-fitting clothing, jewellery, or other items that could become entangled in machinery

- Hazardous mechanical motions and actions, such as unexpected start-ups

- Power-driven machines, which can cause serious injuries when operated without proper guarding

2. Compliance with Regulations

Mechanical plant must adhere to strict safety regulations and guidelines governing bodies, such as:

- AS 4024.1-2014 Series – Safety of Machinery that specifies requirements for designing guards, protective structures, and other safety features for machinery to prevent accidents from using such equipment.

- The Department of Mines, Industry Regulation and Safety in Western Australia guides guarding, ensuring that dangerous parts are safely protected, designed, and constructed to prevent the operator from the danger zone during normal operation.

- AS/NZS 2153.1:1997 is a joint Australian/New Zealand standard that specifies requirements for designing tractors and machinery for agriculture and forestry to prevent accidents from using such equipment. The standard provides technical means for ensuring safety in general. It covers aspects such as the design of guards, protective structures, and other safety features.

Failure to comply can result in penalties and legal consequences. Employers can protect their workers from hazards by implementing safety solutions, proper machine safety guarding in mechanical plant and adhering to relevant regulations.

3. Improved Productivity

In addition to protecting workers from harm, machine guarding can enhance productivity by minimising downtime resulting from accidents. Providing a safe and secure environment is essential for boosting productivity. Machinery guards instil confidence in workers, allowing them to focus on their tasks without constant worry about potential accidents.

4. Reduced Downtime

Accidents and injuries in mechanical plant can lead to significant downtime for repairs and investigations. Machinery guarding helps prevent such incidents, reducing the likelihood of unplanned downtime. This not only saves time but also minimises disruptions in the production process.

5. Employee Morale and Retention

Prioritising employee health, safety, and well-being contributes to a positive work environment. Machinery guarding demonstrates an employer's commitment to the welfare of its workforce, boosting employee morale and satisfaction. This, in turn, improves retention rates and reduces the costs associated with recruitment and training.

6. Cost Savings

Proper machine guarding can save businesses money by reducing the costs associated with injuries, downtime, recruitment and training. Additionally, investing in machine guarding can help companies to qualify for insurance discounts.

Essential Components of Machine Guarding

The components of a complete machine guarding system include:

Risk Assessment and Hazard Identification

Conducting a comprehensive risk assessment before implementing any machinery guarding protocols is imperative. This process involves identifying hazards associated with the machinery and assessing their risk level.

Physical Guards

Physical guards act as a physical barrier between workers and hazardous machine components. These guards shield and safeguard from unintended contact with dangerous moving parts, sharp edges, and potentially dangerous debris. They can be fixed, adjustable, or interlocked, depending on the machinery's operation and accessibility requirements.

Interlocks and Safety Devices

Interlocks, personal safety, and devices are additional measures that enhance machinery safety. Interlocks prevent or control access to hazardous areas during machine operation. Safety devices, such as light curtains and safety mats, can detect the presence of a person and automatically stop the machine to prevent injuries.

Emergency Stop Systems

Emergency stop systems are crucial for quickly halting machinery in an emergency. They provide a readily accessible means for workers to stop the machine's operation if they perceive an immediate danger. Emergency stop buttons should be marked, easily identifiable, and within reach of all machine operators.

Training and Awareness Programs

Proper training and awareness programs are vital to ensure workers understand the risks associated with machinery and know how to operate equipment safely. Employers should provide comprehensive training to all employees who work with or near machinery. This training should cover hazard identification, safe operating procedures, and emergency response protocols.

Maintenance and Inspection

Maintenance and inspection of machine guarding systems are essential to ensure their continued effectiveness. Employers should establish maintenance schedules and conduct routine checks to identify signs of wear, damage, or malfunction. Prompt repairs or replacements should be carried out to maintain the integrity of the guarding system.

Warning Signs and Labels

Warning signs and labels should be posted around machinery to warn workers of potential risks. These can include hazard symbols, danger notices, or instructions on operating equipment safely. Use warning signs with physical guards to alert workers of the associated hazards.

Compliance and Documentation

To demonstrate due diligence and comply with legal requirements, businesses must maintain detailed documentation on machinery guarding. This documentation should include risk assessments, maintenance records, inspection reports, training logs, and any modifications or upgrades made to the guarding.

Best Practices for Machine Guarding

1. Understand the Importance of Machine Guarding

Machinery guarding protects workers from hazardous machine parts and prevents accidents. It involves implementing physical barriers, safety devices, and engineering controls to prevent contact and minimise the risk of injuries. Effective machinery guarding creates a safe work environment and boosts employee morale and productivity.

2. Identify Hazards and Risks

Before implementing machinery guarding measures, conducting a comprehensive hazard assessment is essential. Identify potential hazards of each machine, such as rotating parts, pinch points, or flying debris. Assess the risks involved and prioritise the implementation of appropriate safeguards and guarding methods based on the severity of the hazards.

3. Select Appropriate Guarding Methods

Choose the appropriate guarding methods based on the identified hazards and the type of machinery. Common guarding techniques include fixed guards, interlocked guards, adjustable guards, and presence-sensing devices. Consider the machine's functionality, maintenance requirements, and operator access while selecting the guarding method.

4. Conduct Regular Inspection and Maintenance

Regular inspection and maintenance are essential for the ongoing effectiveness of machinery guarding. Develop an assessment schedule to identify any damage or deterioration in guarding equipment. Train employees to report any issues promptly and address them immediately to maintain a safe working environment.

5. Train and Educate Employees

Proper training and education are critical for employees who operate or work around machinery. Train them on the importance of machinery guarding, the risks involved, and how to use guarding devices correctly. Promote a safety culture, encourage employees to participate in safety programs, and report concerns actively.

6. Evaluate and Update Guarding Measures

Periodically evaluate the effectiveness of guarding measures to identify gaps or improvement areas. Engage with employees and gather feedback on the usability and functionality of the guarding methods. Based on the evaluation, update and improve the guarding measures to address any identified shortcomings.

7. Provide Personal Protective Equipment

Working with hazardous machinery requires employees to wear personal protective equipment (PPE). Employers should provide and ensure proper use of PPE like safety glasses, hearing protection, face shields, gloves, and other items. Ensure the PPE is comfortable and fits appropriately to reduce the risk of injuries.

8. Enhance Communication and Reporting Systems

Establish clear communication channels and reporting systems to ensure that employees can report hazards or malfunctions promptly. Encourage an open dialogue between workers and supervisors regarding machinery safety concerns. Implement a system for documenting reported issues, investigating incidents, and implementing corrective actions.

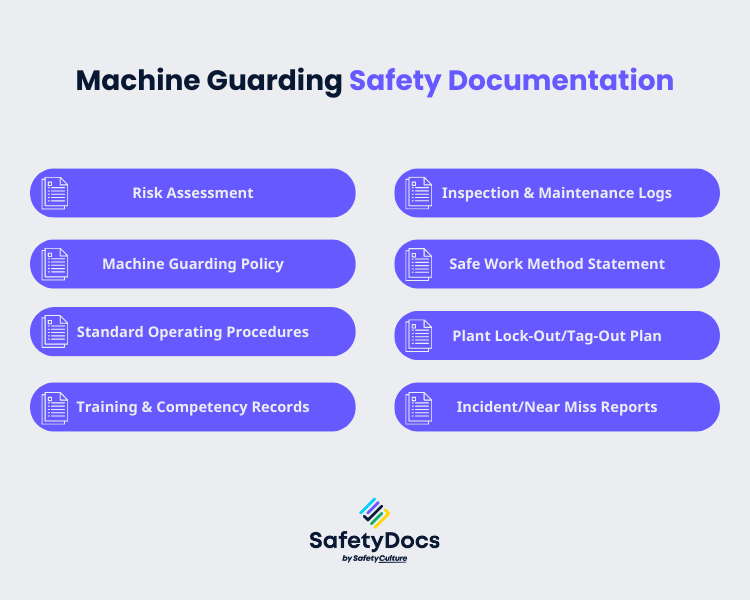

Machine Guarding Safety Documentation

Businesses must maintain comprehensive machinery guard documentation to comply with legal requirements and demonstrate due diligence. This should include the following:

Risk Assessment

Conduct a thorough risk assessment that identifies potential hazards associated with each machine and evaluates the level of risk. This assessment should consider factors such as:

- Types of machines and their functions

- Location and layout of machines

- Frequency and duration of machine use

- Potential hazards, including pinch points, rotating parts, flying debris, and electrical hazards

- Existing safety measures and their effectiveness

Document and review risk assessments periodically to address all hazards effectively.

Machine Guarding Policy

Develop a clear and concise machine-guarding policy outlining the company's commitment to maintaining safe machinery and protecting workers from potential hazards. The policy should include the following:

- The purpose and scope of the policy

- Roles and responsibilities of management, supervisors, and employees

- General safety guidelines for machine operation and maintenance

- Procedures for selecting, installing, and maintaining appropriate guards

- Training requirements for employees working with machinery

Standard Operating Procedures (SOPs)

Create detailed standard operating procedures (SOPs) for each various machine component, specifying the correct methods for operating, maintaining, and troubleshooting the equipment. These SOPs should include information on the following:

- Safe startup and shutdown procedures

- Proper use of machine guards and other safety devices

- Maintenance schedules and procedures, including lock-out/tagout protocols

- Emergency procedures, such as stopping the machine and evacuating the area

Training and Competency Records

Maintain records of employee training and competency assessments related to machine guarding safety. This documentation should include the following:

- Dates and details of training sessions

- Names and qualifications of trainers

- Topics covered during training

- Employee competency assessments and evaluations

Regularly update these records to ensure all employees receive ongoing training and demonstrate the necessary skills to operate machinery safely.

Inspection and Maintenance Logs

Keep logs of machine inspections and maintenance activities, including:

- Dates and details of inspections, including any identified hazards or issues

- Actions to address identified hazards or issues

- Maintenance activities performed, including parts replaced or repaired

- Names and qualifications of individuals conducting inspections and maintenance

Review these logs regularly to ensure that machinery remains in safe working condition and identify recurring trends or issues needing attention.

Safe Work Method Statement (SWMS)

Develop a safe work method statement (SWMS) for each machine specifying the steps and precautions required to safely use, maintain, and inspect the equipment. This document should include the following:

- A detailed description of tasks related to machine operation and maintenance

- Hazards associated with these tasks

- Risk control measures

- Safety precautions

Plant Lock-out/Tag-out Plan

The lock-out/tag-out (LOTO) plan should include detailed procedures for controlling hazardous energy sources when working on or near machines. This includes isolating electrical, mechanical, hydraulic, and pneumatic power sources to prevent unintended activation. The LOTO plan should describe the following:

- Types of energy sources that need to be controlled

- Procedures for isolating and controlling hazardous energy sources

- Roles and responsibilities of personnel involved in the LOTO process

- Required lock-out devices and tags

Use LOTO SWMS or a LOTO SOP where appropriate to ensure consistent implementation of the plant LOTO plan. Additionally, create a log to track all lock-outs and tag-outs performed on machines as an added safety measure.

Incident/Near Miss Reports

Maintain records of incidents and near misses involving machinery, including:

- Names of personnel involved in the incident/near miss

- Description of the incident, including date, time, and location

- Steps taken to address the incident/near miss

- Identification of any root causes or contributing factors

By documenting these incidents and identifying any patterns or trends, businesses can take steps to improve safety practices and prevent future accidents.

Successful Machinery Guarding Implementation

These individual components, such as risk assessments, machine guarding policies, SOPs, training records, inspection logs, lock-out/tag-out plans, and incident/near miss reports, are essential elements of an effective machine guarding safety program. However, managing and organising these components can be challenging without a cohesive framework. That's where a Machine Guarding Management Plan comes in.

A Machine Guarding Management Plan integrates all these components into a comprehensive and streamlined system. It provides a centralised approach to managing machine guarding safety documentation, ensuring that all necessary elements are in place and easily accessible. By incorporating these components into a cohesive plan, businesses can benefit from the following:

1. Efficiency and Organisation:

A Machine Guarding Management Plan combines all the necessary documentation and resources in one place. This streamlines processes, enhances efficiency, and simplifies record-keeping, making it easier for businesses to manage and maintain their machine guarding safety program.

2. Compliance with Standards and Regulations:

A Machine Guarding Management Plan is designed to align with relevant standards and regulations, such as those set by regulatory bodies like Safe Work Australia. By adopting this plan, businesses can demonstrate compliance and ensure that their machine-guarding practices adhere to legal requirements.

3. Consistency and Standardisation:

A well-structured Machine Guarding Management Plan provides consistent guidelines and procedures for machine operation, maintenance, and safety. This standardisation helps eliminate inconsistencies, reduces the risk of errors, and promotes a culture of safety throughout the organisation.

4. Improved Risk Management:

The plan's systematic approach, including risk assessments and regular inspections, helps businesses identify and mitigate potential hazards. By implementing risk control measures outlined in the plan, organisations can proactively manage risks, reduce accidents, and create a safer work environment.

5. Ongoing Training and Competency:

The Machine Guarding Management Plan emphasises the importance of training and competency assessment. By maintaining training records and incorporating them into the plan, businesses can ensure that employees receive ongoing training, refreshers, and evaluations to enhance their skills and knowledge of machine guarding safety.

Incorporating these individual components into a Machine Guarding Management Plan provides businesses with a comprehensive framework for managing and enhancing their machine-guarding safety program. It promotes organisation, compliance, risk management, and ongoing improvement.

To learn more about our Machine Guarding Management Plan, visit our product page here.

Streamline Compliance Efforts with SafetyDocs Machine Guarding Documentation

Businesses must maintain comprehensive safety documentation to demonstrate compliance with legal requirements and protect workers from machine-guarding hazards associated with working with machinery. SafetyDocs by SafetyCulture offers many resources, including risk assessments, policies, SOPs, checklists, training materials, and more. We help businesses create and maintain successful machine-guarding safety documentation.

With SafetyDocs, your business will have the necessary documentation to protect workers while meeting legal requirements.

Get started today for a safer workplace tomorrow.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article