In 2021, Australia recorded a total of 169 worker fatalities due to workplace accidents. Additionally, a report comparing survey data from the Australian Bureau of Statistics with SWA's data shows that in 2021-22, 3.9% of employed people experienced a work-related injury or illness, down from 4.2% in 2017-18 and 6.4% in 2005-06. On average, just under 200 workers in Australia are fatally injured annually.

The data shows that health and safety in the workplace is a crucial aspect of any organisation's operations — not only in Australia but around the world. To ensure that you are maintaining a safe work environment for your staff and to reduce workplace accidents and injuries, you should consider implementing a safety management plan.

What is a Safety Management Plan?

In many countries worldwide, including Australia, there are regulations that require companies to have formal Safety Management Plans or Work Health and Safety (WHS) Management Plans in place. These plans are particularly critical in industries where there is a high risk of accidents, such as construction, manufacturing, mining, and chemicals.

Mandatory Safety Management Plans: In certain scenarios, safety management plans are mandatory and must comply with specific laws and regulations. For instance, in Australia, principal contractors involved in construction projects are legally required to develop and implement a WHS Management Plan before starting work. This plan must include detailed information regarding health and safety policies, risk management processes, safety training programs, subcontractor management, procedures for dealing with injuries, and systems for monitoring and reviewing the plan’s effectiveness.

These legal requirements ensure that organisations adopt systematic approaches to identify, assess, and control risks that may arise during work activities. This is especially vital in high-risk environments where the health and well-being of workers and the general public could be affected. Non-compliance with these legal requirements can lead to penalties, fines, and even suspension of operating licences.

It's imperative for organisations, especially those in industries like construction, to be aware of the specific safety management plan requirements that pertain to their state or territory. Regulatory requirements can differ significantly across jurisdictions.

For example, in Queensland, Australia, a construction project requiring a safety management plan is defined as one where the cost of the construction work is $250,000 or more. In contrast, Western Australia stipulates that a safety management plan is necessary for construction projects where five or more persons are, or are likely to be, working at the same time.

Such discrepancies in regulations emphasise the importance of thorough research and consultation with legal experts to ensure compliance with all applicable laws and regulations in the respective state or territory. Not only does this adherence protect the well-being of employees, but it also safeguards \against legal penalties and reputational damage.

Voluntary Safety Management Plans: Apart from the legal requirements, organisations might also develop safety management plans voluntarily to better manage a particular aspect or to meet best practice standards. These plans are typically more flexible and can be tailored to address an organisation’s specific challenges. For instance, a company might want to implement a safety management plan to reduce repetitive strain injuries among office workers, even if it is not mandated by law.

What are the Purposes of a Safety Management Plan?

The purposes of a Safety Management Plan are:

- To provide organisations with strategies and measures that permit the prevention of accidents, identification of hazards, reduction of risks, and protection of workers

- To clarify the roles and responsibilities of everyone involved in conducting high-risk activities

- To define and communicate work health and safety (WHS) arrangements and prioritise goals to achieve a safer workplace

- To make health and safety an integral part of a business's core operations

- To manage reporting, responsibilities, planning, and resourcing to create a safer workplace

- To ensure that workers are subject to ongoing supervision

- To be a strategic action plan that forms part of the business plan

Key Elements of Safety Management Plans

Developing an effective safety management plan requires a thorough understanding of each element and how they interconnect. Let's take a closer look at each element

1. Description of the work

This section outlines the type of work that is to be undertaken and any associated hazards. A comprehensive SMP begins with a detailed description of the work. This includes the scope, objectives, and deliverables of the project. Describing or detailing the work ensures that everyone involved in the project is aware of what needs to be done and any associated risks.

2. Roles and responsibilities

Clearly defined roles and responsibilities for all employees, supervisors, and management in implementing and maintaining the safety management plan. Everyone should know what their duties are in ensuring a safe work environment.

3. Hazard identification

The next step involves conducting a thorough hazard identification process. This entails identifying and assessing potential risks and hazards that employees may encounter during the course of their work. Hazards can include physical, chemical, biological, and ergonomic factors, as well as any other risks that could compromise the health and safety of employees.

4. Risk assessment

Once hazards are identified, a comprehensive risk assessment is conducted. This involves evaluating the likelihood and severity of each identified hazard. Risk assessment enables organisations to prioritise and address critical risks effectively. It helps determine the necessary control measures to minimise or eliminate the potential harm posed by identified hazards.

5. Control measures

Control measures are proactive steps taken to minimise or eliminate risks. These measures can include engineering controls, administrative controls, health and safety rules and personal protective equipment (PPE). Organisations must provide detailed information on the control measures to be implemented, including their effectiveness and any necessary training for employees.

6. Emergency procedures

In the event of an emergency, well-defined procedures must be in place to ensure a prompt and organised response. SMPs should outline the necessary steps to be taken during emergencies, including evacuation procedures, communication protocols, and the availability of emergency response resources.

7. Training and induction

Regular training and education programs are crucial in maintaining a safe work environment. They ensure that employees are well-informed about potential hazards, follow safe work practices, and are proficient in using personal protective equipment (PPE).

8. Safety performance monitoring and measurement

Tracking and analysing key performance indicators (KPIs) related to safety are essential for assessing safety performance. This includes monitoring employee safety behaviour, incident and accident rates, and identifying patterns that may be indicative of systemic issues. Regular safety audits and inspections should also be conducted to ensure that safety protocols are followed.

9. Continuous improvement

Safety management plans must include a process of assessment monitoring and review, for ongoing review and improvement. This includes reviewing existing safety protocols and measures to ensure that they are still effective. The feedback from employees, contractors, suppliers, and other stakeholders should also be taken into account to identify areas for improvement.

10. Signatures of all workers involved

To ensure accountability and commitment to safety, SMPs should require the signatures of all workers involved in the project. This signifies their acknowledgment and understanding of the various safety rules and protocols outlined in the plan. This ensures that everyone involved in the project understands their roles and responsibilities in maintaining a safe work environment.

Examples of Safety Management Plans

To develop a safety management plan, organisations must have a clear understanding of each element and its significance. For example, in the construction industry, the description of the work may include details about specific tasks, equipment used, and the sequence of activities. On the other hand, a psychosocial hazards management plan in the healthcare sector may focus on identifying and addressing workplace stressors.

Here are some examples of top-selling Safety Management Plans from SafetyDocs that have proven effective in various industries:

- Psychosocial Hazards Management Plan: Designed to address psychological and social risks in the workplace, this plan helps organisations identify and manage stressors, interpersonal conflicts, and other factors that can impact employee well-being.

- Silica Dust Management Plan: A plan specifically tailored to industries where workers are exposed to silica dust, such as construction and mining. It outlines control measures, respiratory protection, and air monitoring procedures to prevent exposure-related health issues.

- Waste Management Plan: This plan focuses on proper waste disposal and recycling practices to minimise environmental impact. It includes guidelines for waste segregation, spill management, erosion and sediment management, and disposal methods.

- Construction Traffic Management Plan: Aimed at construction sites, this plan addresses traffic management, vehicle movements, and pedestrian safety. It outlines procedures for traffic control, signages, and the separation of construction and public areas.

- Environmental Site Management Plan for Construction: This plan focuses on minimising the environmental impact of construction activities aligned with AS/NZS ISO 14001:2016. It includes the essential documents, forms, and checklists for effective environmental management.

- Chain of Responsibilities Management Plan: Particularly relevant in transportation and logistics, this plan ensures clear lines of accountability and responsibility for all parties involved in the supply chain. It outlines procedures for load securing, fatigue management, vehicle maintenance, and compliance with regulations.

- Construction HSEQ Site Management Plan: HSEQ stands for Health, Safety, Environment, and Quality. This plan integrates these aspects to ensure compliance with industry standards and regulations. It outlines procedures for hazard identification, risk assessment, incident reporting, and quality assurance on the construction site.

- Quality Project Management Plan: This plan focuses on ensuring the quality of project deliverables. It includes procedures for quality control, inspections, testing, and documentation that impact the quality of the organisation's processes, services, or products.

- Electricians Safety Management Plan: Specifically designed for electrical safety, this plan addresses hazards and procedures for personnel working with high-voltage equipment, wiring, and tools. It includes documents such as lockout/tagout procedures, working with live wires policies, and equipment registers.

- Workplace Fatigue Management Plan: Fatigue is a significant concern in industries with long working hours or shift work. This plan's purpose is to identify and reduce risks concerning fatigue and to provide adequate resourcing to prevent fatalities, injuries or illnesses.

- Manual Handling Management Plan:This plan offers policies and procedures aimed at preventing injuries associated with manual tasks. This is accomplished by identifying hazardous manual tasks and implementing suitable risk control measures.

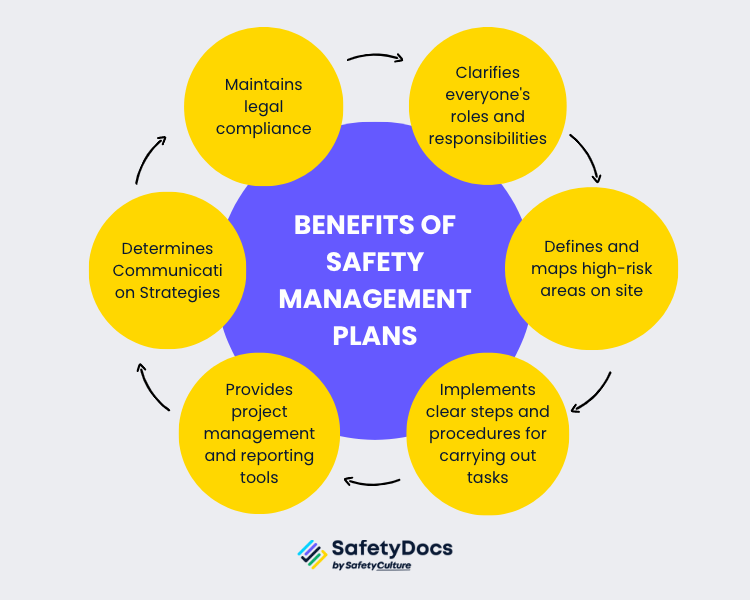

Benefits of Safety Management Plans

When you effectively implement an SMP by incorporating its key elements or utilising a template, you can expect to see several benefits.

Clarifies everyone's roles and responsibilities

A well-developed safety management plan clearly defines the roles and responsibilities of individuals and teams, ensuring everyone understands their obligations and contributes to a safer work environment.

Defines and maps high-risk areas on site

Safety management plans help identify high-risk areas, allowing organisations to implement targeted control measures and allocate resources efficiently to mitigate potential hazards.

Implements clear steps and procedures for carrying out tasks

By outlining clear steps and procedures, safety management plans ensure that tasks are performed consistently and safely. This reduces the likelihood of accidents and injuries.

Provides project management and reporting tools

Safety management plans often include project management tools, such as checklists, incident reporting forms, and documentation templates. These tools streamline safety processes, making them more efficient and effective.

Determines Communication Strategies

Safety management plans to establish communication channels and protocols for reporting incidents, sharing safety-related information, and ensuring effective communication among workers and management.

Maintains legal compliance

Safety management plans help organisations meet their legal obligations by incorporating regulatory requirements and industry best practices into their safety procedures. This reduces the risk of non-compliance and associated penalties.

Get Started With SafetyDocs

Knowing how SMPs can benefit your organisation, you may be wondering how to create one. You don't need to. Save time and resources by using our customisable safety management plans.

SafetyDocs by SafetyCulture offers a variety of safety management plans, safe work method statements, and a lot more documents that you can tailor to your organisation's needs. Our plans include a wide range of topics, from general safety management to site-specific health and safety in different industries. With our products, you can enjoy:

- Instant document delivery via email

- Easy adding to your existing management system

- Easy adaptation as customisation instructions are provided

- On-the-go editing of documents with the Microsoft Office Mobile App

- One-time payment with no subscriptions required

Start building a safe and compliant work environment with SafetyDocs. Contact us today to get the best safety management plans that are fit for your workplace, or use the finder below!

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article