Imagine a workplace where machinery maintenance or servicing activities are done without any fear of unexpected startups or the control of hazardous energy or releases. Is this not an ideal scenario?

In May 2022, a worker suffered severe de-gloving injuries when his hand became trapped in a curtain-coating roller machine. Just a month later, another worker lost his life after being pulled off position and into the drive shaft of a conveyor. These incidents highlight a critical aspect of workplace safety: the importance of Lockout/Tagout (LOTO) procedures.

What is a Lockout/Tagout Procedure

Lockout/Tagout (LOTO) is a crucial safety procedure in industrial processes. It ensures that dangerous machines are properly shut off and can't be restarted until maintenance or repair work is done. LOTO procedures safeguard workers against sudden hazardous energy release, preventing potentially fatal injuries.

Key Terms and Definitions

- Energy Sources: These are hazardous energy sources that must be isolated during maintenance or repair work. They can include electrical, mechanical, hydraulic, pneumatic, chemical, thermal, and other energy sources.

- Lockout Device: A physical lock placed on an energy isolation device to prevent it from being operated.

- Tagout Device: A tag or label attached to an energy-isolating device to warn workers not to operate it.

- Energy Isolation Devices: The physical mechanism that prevents the release of hazardous energy, such as circuit breakers, valves, or switches.

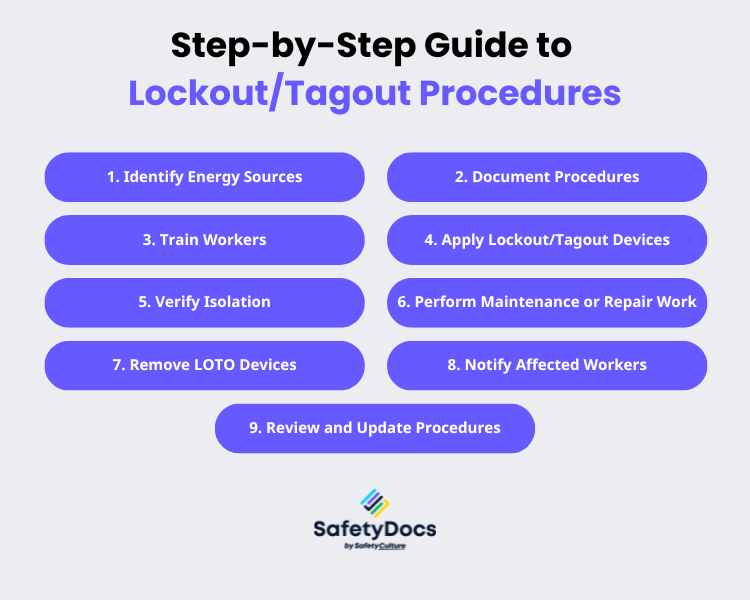

Step-by-Step Guide to Lockout/Tagout Procedures

To effectively implement LOTO procedures, follow these eight steps:

1. Identify Energy Sources

The first step is to understand and identify the various hazardous energy sources that power your equipment. Hazardous energy sources can be:

- Electrical: Look for power sources such as outlets, generators, or batteries.

- Mechanical: Identify moving parts like gears, belts, and conveyor systems.

- Hydraulic and Pneumatic: Check for fluid and air pressure systems, including lines and valves.

- Chemical: Know storage tanks, pipelines, and any areas where chemicals are stored or used.

- Thermal: They are heat-generating equipment such as furnaces and boilers.

Conduct an audit for each piece of equipment to identify and document all potential hazardous energy sources. Use equipment manuals, schematics, and input from experienced staff to ensure nothing is overlooked.

2. Document Procedures

Once you have identified the energy sources, the next step is to create detailed, machine-specific LOTO procedures. Thorough documentation of these procedures is crucial, making them readily available to all staff members. Here are the essential elements of a standard LOTO energy control procedure:

- Shutdown: Outline the steps to turn off the equipment safely.

- Isolation: Steps to isolate all hazardous energy sources, including locking and tagging them.

- Verification: A method for verifying that all energy sources have been completely de-energised before maintenance begins.

3. Train Workers

While specific lockout tagout (LOTO) training requirements may vary across different industries, the underlying principle of ensuring worker safety through proper training is universally emphasised.

Workers who are directly responsible for executing LOTO procedures should be equipped with the knowledge and skills to isolate and de-energise equipment safely. Similarly, affected workers working near LOTO operations should be adequately informed about the purpose and significance of these procedures to guarantee their well-being and prevent any inadvertent interference with LOTO measures.

To achieve this, comprehensive training programs should cover:

- Identifying and controlling hazardous energy sources

- Properly use devices like lockout devices, tags, and energy isolation devices.

- Importance of following procedures step-by-step

- Risks associated with failure to follow hazardous energy control procedures

Training must also cover relevant Australian standards such as:

- AS/NZS 4836:2011 - Safe working on or near low-voltage electrical installations and equipment: Provides safety guidelines for low-voltage electrical work, including risk management, asbestos handling, underground work, cable cutting, test equipment use, and personal protective equipment (PPE).

- AS 4024.1603-2006 - Safety of machinery: outlines requirements and recommendations for designing, constructing, and modifying machinery to protect against mechanical hazards. It covers risk assessment, safety distances, interlocking guards, and control systems.

4. Apply Lockout/Tagout Devices

Once the equipment has been shut down and you effectively isolate all energy sources, lockout/tagout devices must be applied. These devices include:

- Padlocks: Used to secure energy isolation devices such as switches and valves.

- Tags: These must be attached to lockout devices, indicating who applied them, the date and time of application, and any relevant safety warnings.

- Lockout hasps: Used to lock multiple energy isolation devices together.

- Valve lockouts: Secure valves either in the closed or open position.

- Electrical lockouts: Prevents access to outlets and switches.

- Circuit breaker lockouts: Prevents circuits from being switched on.

5. Verify Isolation

Before maintenance work begins, the machine must be thoroughly checked to ensure all energy sources are entirely isolated. A systematic approach is needed to validate the effective isolation of all hazardous thermal energy sources. The following can be used to verify isolation:

- Risk Assessment Checklists

- Visual Inspections

- Electrical Testers

- Measurement Tools (such as pressure gauges or thermometers)

6. Perform Maintenance or Repair Work

Maintenance or repair work can begin once the equipment has been safely locked out, and all energy sources have been isolated and verified. Follow these safe work practices:

- Depending on the equipment and work involved, workers may need protective gear such as gloves, goggles, or ear protection.

- Utilise the right tools and equipment for the task at hand.

- Ensure no hazards in the work area, such as chemicals or loose objects.

- Follow the maintenance or repair guidelines specified in the equipment manual.

7. Remove LOTO Devices

Once maintenance work is complete, the person who applied them must remove all LOTO devices. Before removing the devices, workers should ensure that:

- The equipment has been reassembled and is ready to be energised.

- All tools and maintenance equipment have been removed from the work area.

- No workers or contractors are in harm's way.

- Confirm that guards and safety devices are correctly reinstalled.

- Follow the documented re-energisation procedures to restore power safely.

Document the removal process and conduct a final check to ensure the equipment operates correctly and safely.

8. Notify Affected Workers

It is essential to inform affected personnel that the lockout/tagout devices have been removed and that the equipment is back in operation. This notification is a safety precaution to ensure no one inadvertently enters the area while maintenance work on dangerous equipment is completed.

9. Review and Update Procedures

LOTO procedures should not be considered static documents; they must be reviewed regularly to ensure they are up-to-date with equipment changes, new occupational safety regulations, or workplace incidents. It's also essential to review procedures after every maintenance shutdown to identify any areas for improvement.

Why are Lockout/Tag Out Procedures Important?

As mentioned, LOTO procedures are crucial for worker safety during maintenance activities. Here are several reasons why LOTO procedures are indispensable to protect workers in any Australian workplace:

Preventing Injuries and Fatalities

Accidents caused by the abrupt discharge of energy can result in severe injuries like electrocution, electrical shock, amputation, burns, and crushing. Tragically, these incidents often result in permanent disability or death.

Compliance with Regulations

In Australia, workplace safety is governed by legislation such as the WHS Act and the relevant Codes of Practice. The person conducting a business or undertaking (PCBU) is responsible for providing workers with safe work practices and procedures, and LOTO procedures are an essential part of that.

PCBU Responsibilities for LOTO Compliance

- Duty of Care: PCBUs must ensure worker and public health and safety, including effective LOTO procedures.

- Provision of Information and Training: PCBUs must provide necessary LOTO information, training, and supervision.

- Duty to Consult: PCBUs must consult workers on LOTO and safety matters.

- Responsibility to Others: PCBUs must protect customers, visitors, and the public from LOTO-related risks.

- Incident Reporting: PCBUs must report serious LOTO incidents to regulators.

- Record Keeping: PCBUs must maintain records of LOTO training, procedures, and audits.

- Continual Improvement: PCBUs should improve their energy control program to enhance safety.

Reducing Downtime and Costs

Accidents harm workers and disrupt normal production operations and processes. Implementing effective LOTO procedures minimises the risk of accidents. It reduces costs associated with medical expenses, workers' compensation claims, and equipment repairs.

Protecting Equipment and Infrastructure

Improperly managed energy sources can damage machinery and infrastructure. When properly locked out, equipment remains stationary and cannot be accidentally re-energised, reducing the risk of equipment damage and costly repairs.

Promoting a Culture of Safety

Implementing and enforcing LOTO procedures fosters a culture of safety in the workplace. When workers see that their occupational safety and health are a priority, they are more inclined to follow safety protocols and actively contribute to establishing a secure work environment.

What Industries Require a Lockout/Tagout Procedure

Lockout/Tagout (LOTO) procedures are relevant across various industries where machinery and equipment maintenance operations are routine. These sectors include, but are not limited to:

- Manufacturing: This industry heavily relies on machinery for production processes.

- Construction: Construction sites often involve complex machinery and equipment that require regular servicing.

- Automotive: LOTO auto manufacturing and repair procedures ensure worker safety by isolating heavy machinery and equipment.

- Chemical Plants: LOTO procedures are essential to safeguard workers from chemical spills, explosions, and other hazardous energy releases.

- Utilities: Utility companies often use high-voltage equipment that must be locked out before maintenance activities occur.

- Mining: Mining sites typically have large and complex equipment that must be adequately locked out to prevent accidents and injuries.

- Transportation: LOTO procedures prevent accidents and injuries during maintenance activities on trains, planes, and other transportation equipment

A Safe Workplace is a Productive Workplace

Following the step-by-step LOTO procedures outlined in this guide will help keep your workers safe and minimise the risk of accidents and injuries. Complete these steps using the right tools and documentation. SafetyDocs by SafetyCulture offers a range of safety documentation, including LOTO procedures, to help you create a safer work environment.

- Plant Lockout/Tag-out Plan

- Lock Out Tag Out - LOTO Safe Operating Procedure

- Machine Guarding Management Plan

- Plant Safety Management Plan

Investing in a robust LOTO program isn't just about safety. It's about protecting your most valuable asset - your workers. With SafetyDocs expert guidance, you can create a safer workplace, reduce downtime, and avoid costly accidents.

Visit SafetyDocs today to learn more about our LOTO resources and invest in a safer future for your business.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article