Jun 11th 2024 |

How to Conduct a Thorough Workplace Hazard Assessment: A Step-by-Step Guide Aligned with Safe Work Australia

Globally, nearly three million workers die every year due to work-related accidents and diseases, according to the International Labour Organization (ILO). The issue of workplace fatalities remains a major concern, and numbers from Safe Work Australia's reports indicate that Australia, specifically, has been recording a steady number of work-related deaths in recent years.

In 2021, 169 workers died while performing their work. The following year saw a rise in workplace fatalities, with 195 workers suffering traumatic injuries in 2022. By December 7, 2023, the death toll stood at 147, and preliminary data for 2024 already indicates that 173 workers have suffered fatal injuries. These statistics underscore the continuous need for enhanced safety measures and protocols in Australian workplaces.

Hazard identification plays a pivotal role in reducing workplace fatalities and injuries by systematically identifying and assessing potential hazards, thereby enabling the implementation of effective control measures.

Workplace hazard assessment is a crucial step in mitigating occupational risks, preventing workplace injuries, and ultimately reducing fatalities. This guide will take you through the essential steps to conducting a thorough hazard assessment aligned with the Safe Work Australia (SWA) guidelines.

Step 1. Understanding Codes of Practice

Codes of practice offer practical guidance on complying with work health and safety (WHS) laws and regulations within a certain industry or for a specific hazard. They provide detailed steps and best practices to help businesses create safe workplaces. While not legally binding in themselves, following a code of practice is a strong way to demonstrate that you're taking reasonable steps to fulfil your safety obligations.

Examples of Codes of Practice

- Industry-specific: Construction Work Code of Practice, Managing Electrical Risks in the Workplace Code of Practice, etc.

- Hazard-specific: Confined Spaces Code of Practice, Hazardous Manual Tasks Code of Practice, etc.

The Role of Safe Work Australia’s 'How to Manage Work Health and Safety Risks' Code of Practice

This particular Code of Practice provides a broad, foundational framework for identifying and managing hazards across all types of workplaces. By following its guidance, businesses can:

- Establish a Systematic Approach: The Code helps you break down complex safety issues into manageable steps, ensuring nothing gets overlooked.

- Tap into Best Practices: Its recommendations are based on proven safety practices from a range of industries.

- Demonstrate Compliance: Aligning with the Code shows you're committed to due diligence in workplace safety.

What is Hazard Assessment

A hazard assessment involves identifying, evaluating, and managing safety and health hazards in the workplace to safeguard worker well-being. It starts with the crucial step to identify hazards, including recognising and understanding potential hazards through incident investigations, risk assessments, workplace surveys, and proactive inspection processes. Identifying common workplace hazards and checking for any obvious hazards using a hazard identification checklist is an important first step in the hazard identification process.

It is all about figuring out what hazards are present at work, how serious their risks are, and what we can do to stop or prevent them from happening. Simply put, a hazard assessment involves identifying potential hazards in the workplace, assessing the risks associated with these hazards, implementing control measures to mitigate risks, and maintaining records to track and review the effectiveness of these measures.

Part of this process includes prioritising hazards and determining which hazards should be addressed first to reduce overall risk effectively.

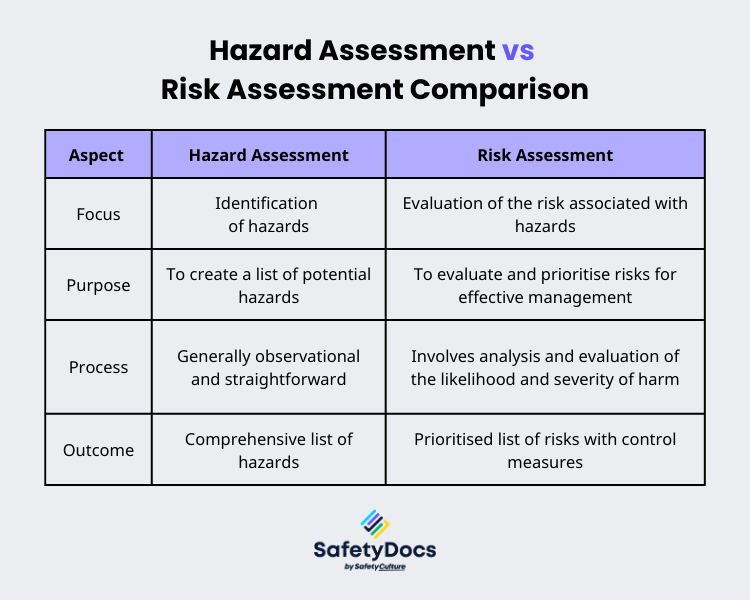

Hazard Assessment vs Risk Assessment

Hazard and Risk assessments are fundamental components of workplace safety and health management. Though they are closely related and often used interchangeably, they serve different purposes and focus on distinct aspects of safety management.

(1) Hazard Assessment

Hazard Assessment is identifying potential hazards that could cause harm in a workplace. A hazard is anything that has the potential to cause harm, such as chemicals, electricity, working at height, or even an open drawer. The main goal of Hazard Assessment is to create a comprehensive list of hazards present in the workplace. It involves inspecting the workplace, reviewing records, and consulting safety standards to find physical, chemical, ergonomic, biological, or psychosocial hazards.

Key points about Hazard Assessment:

- It focuses on identifying hazardous conditions or substances.

- It is generally the first step in a safety management process because you need to know the potential hazards before assessing how risky they are.

- Hazard assessments are typically simpler than risk assessments, and you can do them through observations and inspections.

(2) Risk Assessment

Builds on hazard assessment by asking: 'How likely is it for something to go wrong, and how bad could it be?' It considers the likelihood of a hazard occurring, the severity of potential injuries or illnesses, and the effectiveness of existing controls.

In simpler terms, hazard assessment is like identifying a fire hazard in your house (e.g., frayed wires), while risk assessment is evaluating how likely it is for that fire hazard to cause a fire (e.g., considering the placement of the wires and flammability of nearby materials) and how bad the fire could be (e.g., potential damage to the house and risk to people living there).

Key points about Risk Assessment:

- Risk Assessment involves analysing and evaluating the risk associated with each identified hazard through a detailed risk analysis process.

- It helps determine which hazards require immediate attention or mitigation measures based on their risk level. The documentation of this process is often captured in a risk assessment form, forming an integral part of an organisation's health and safety management plan.

- The process involves estimating both the likelihood of harm occurring and the potential severity of that harm.

- Risk Assessment is used to prioritise risks and implement appropriate control measures to minimise or eliminate the risks.

Here are four (4) key points to focus on during the hazard assessment phase:

1. Comprehensive Scope: Assess all workplace aspects (tasks, equipment, materials, environment) for potential hazards.

- Work Tasks: The individual steps and processes involved in jobs. For example, a retail worker unboxing stock faces hazards like cuts from box cutters and back strain from lifting or tripping over boxes.

- Equipment & Machinery: Consider both normal operation and potential malfunctions. A forklift, for instance, could strike a worker during operation or pose risks if its brakes or hydraulics fail.

- Materials: Refer to Safety Data Sheets (SDS) for hazardous chemicals. Even seemingly harmless materials like sawdust could be a fire/respiratory hazard in excess.

- Work Environment: Layout, lighting, ventilation, temperature, noise, etc. Poor ventilation in a chemical storage area could make workers dizzy or ill.

2. Worker Involvement: Worker insights are crucial; interview, observe, and provide feedback channels

- Interviews and Discussions: Seek their ideas on what could go wrong and how.

- Observations: Watch them perform their tasks to observe potential issues.

- Feedback Channels: Have an open-door policy or a system for workers to report hazards at any time.

3. Utilise Diverse Resources: Combine walkthroughs, record reviews, and industry standards for thoroughness.

- Walkthroughs: Physical inspections give you direct visual information.

- Reviewing Records: Analyse past incidents, maintenance reports, and safety audits for patterns.

- Consulting Standards and Guidelines: Industry-specific regulations and best practices give a benchmark against which to compare.

- Consider Your Supply Chain: Sometimes hazards are introduced by the way suppliers package materials or the deadlines set by those commissioning work. Engage in open communication throughout your supply chain to identify potential risks and ensure everyone prioritises safety.

4. Focus on the "How" and the "Why": Understand how hazards cause harm and their root causes.

- How could someone be harmed? Be specific. Instead of just saying "slip hazard," think "worker could slip on a wet floor, breaking an arm". This helps with prioritising and choosing the right controls.

- Why does this hazard exist? Understand root causes to choose the best control measures.

Implementing Control Measures

Once you’ve identified hazards (and assessed their risk), it’s time to implement control measures to protect workers. Remember the hierarchy of controls:

- Elimination: Can you get rid of the hazard completely? For example, replacing a highly toxic cleaning product with a safer alternative.

- Substitution: Replace the hazard with something less harmful. For example, quieter machinery can be used to reduce noise-related injury risk.

- Engineering Controls: Isolate the hazard. Install machine guards or redesign a workstation to avoid workers needing to overreach.

- Administrative Controls: Change work practices. This could be job rotation to reduce repetitive strain or providing more training to workers exposed to chemicals.

- Personal Protective Equipment (PPE): Last resort. This includes gloves, masks, ear protection, etc.

Understanding and documenting risk control is crucial in ensuring that the implemented measures effectively manage hazards and protect workers. It also aids in continually improving workplace safety by providing a framework for monitoring and reviewing the effectiveness of control measures.

Balancing Risk vs. Cost:

Businesses have to make smart financial decisions. In a perfect world, we'd eliminate every hazard instantly. But sometimes, that's just not possible. Legally, you must do what's 'reasonably practicable'. This means the effort and cost you put into safety measures should match the level of risk. However, safety should always be a top priority – never compromise it just to save a few dollars.

Practical Examples

- Office Setting: A cluttered walkway with boxes is a tripping hazard. Elimination or substitution isn't always possible, but engineering controls (better storage solutions) or administrative controls (policies about keeping walkways clear) would reduce the risk.

- Warehouse: Forklifts pose hazards. Administrative controls (speed limits, designated traffic paths) are important, as are engineering controls (backup alarms, proximity sensors).

- Construction Site: Fall hazards are serious. Ideally, work is redesigned (elimination) to be done at ground level. If not, guardrails (engineering) are necessary. Harnesses (PPE) would only be used if other controls cannot be implemented.

Implementing control measures effectively often entails significant changes in the workplace, including adapting to new equipment, processes, chemicals, or personal protective equipment (PPE). To ensure successful integration of changes and maintain high safety levels, consider these supporting actions:

- Develop safe work procedures to assist workers in performing tasks and changes.

- Provide adequate training and information on the hazards, controls, and procedures.

- Regular inspections and maintenance of equipment are conducted to ensure proper functioning.

- Supervise work processes to identify potential problems or areas for improvement.

- Encourage open communication between management and employees to address occupational safety concerns promptly.

Review and Update

Control measures can become less effective over time or due to changes in the workplace. Reviewing and updating risk assessments regularly through a structured risk assessment process is crucial when conditions and processes change. The risk assessment form is vital in this process, aiding in regularly reviewing and updating risk assessments to ensure they remain effective and relevant. Situations that necessitate a review of control measures include:

- When new workplace hazards are discovered

- When an incident or near-miss happens

- When changes are made to work processes, equipment, or materials

- When there are changes in Legislation or Industry Standards

- When new information on existing hazards becomes available

- When workforce dynamics change

- When workplace accidents and illness rates increase

- When workers raise feedback or concerns

- When control measures become outdated or ineffective

- Review at regular intervals

Regularly reviewing control measures is a key component of an effective safety management system. It ensures that controls evolve alongside changes in the workplace environment, workforce, and legal requirements, maintaining a safe and healthy workplace. Here are ways to evaluate the effectiveness of your control measures:

- Inspections and Observations: Regularly check the workplace and observe work performance.

- Feedback from Workers: Getting insights from employees on what is working and what isn’t.

- Incident Records: Reviewing records of near-misses and accidents to identify trends.

Step 5: Maintain Records

Recordkeeping is essential for maintaining a safe workplace. It provides a detailed record of all risk assessment processes, control measures, and reviews undertaken. This information can be used to demonstrate compliance with legal requirements and identify areas for improvement in the safety management system. For instance, reviewing past health and safety risks and control measures can help identify potential hazards and develop appropriate controls when planning for a new project.

Records should be kept in a secure, centralised location accessible to all relevant personnel. They should also be organised and easily retrievable. Keep records of:

- Hazard identification records

- Risk assessment reports

- Control measures implementation records

- Reviews and updates made

- Workplace inspections and observations

- Employee training and information records

- Incident records and investigation reports

- Feedback and suggestions from employees

Reinforce Hazard Assessment With the Right Tools

Understanding the steps in assessing workplace hazards includes choosing the appropriate resources and tools to support your safety management system. SafetyDocs by SafetyCulture, Australia's most trusted provider of occupational safety documentation, enables teams to perform hazard assessments with a breeze. It offers customisable templates for risk management processes, control measures forms, checklists, and more.

Simplify your safety management process to keep your workplace safe and compliant. Start with these documents:

- Risk Management Plan

- Risk Assessment Templates

- Safety Management Systems

- Safe Work Method Statement (SWMS) Templates

It's never too late to improve your workplace safety by conducting a hazard assessment. Stay compliant, stay vigilant, and stay safe. Remember, a safe workplace is a productive workplace. So, prioritise safety at all times! Contact us today at SafetyDocs to learn more about our safety solutions.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article