Australia is currently facing a heatwave like no other, with temperatures soaring as high as 49.3 °C (120.7 °F) in places like Geraldton. Severe heatwave warnings have been issued for regions across Western Australia, including Perth, and Queensland, from Cape York Peninsula to Mackay. Cities like Cairns and Townsville are bracing for extreme heat conditions that pose serious risks to public health.

Workers in outdoor and high-risk environments are particularly vulnerable. For employers, this is an urgent reminder of the need to protect workers from heat stress. One proactive step is to create a heat stress management plan.

What is a Heat Stress Management Plan?

A heat stress management plan is a proactive approach to safeguarding workers from the effects of heat in the workplace. It involves identifying potential hazards, assessing risks and environmental conditions, and implementing controls to prevent heat-related health problems. A heat stress management plan typically includes the following:

- Assessment of heat hazards

- Worker education on prevention

- Access to hydration

- Working schedule protocols

- Heat level monitoring

- Work practice adjustments

- Protective gear provision

- Emergency procedures

- Documentation

Understanding Heat Stress and Its Impact

Developing a heat stress management plan begins with understanding the dangers of heat. Heat is a hidden danger in the workplace, capable of causing severe health issues and, in extreme cases, even fatalities.

What is Heat Stress?

Heat stress occurs when the body's natural cooling mechanisms, such as sweating, are ineffective. This imbalance can lead to dehydration, electrolyte loss, and potentially dangerous increases in human body temperature. Heat stress can occur in workplaces with high humidity, direct sunlight, and low air circulation, like working outdoors or in confined spaces.

Symptoms of Heat Stress

During heat stress, the body undergoes several physiological changes as it attempts to regulate the core body temperature. Common symptoms include:

- Heavy Sweating: Excessive sweating as the body tries to cool down.

- Fatigue: Feeling unusually tired or weak.

- Dizziness: A feeling of spinning or losing balance.

- Painful Muscle Cramps: Dry skin, muscle twitching, painful contractions, often due to electrolyte imbalances.

- Nausea: Feeling sick to the stomach or vomiting.

- Headache: Persistent or throbbing pain in the head.

- Rapid Heartbeat: An unusually fast pulse as the body works to cool itself.

- Confusion or Disorientation: Difficulty thinking clearly or feeling confused.

Health and Productivity Impacts

As climate change and extreme heat events become more frequent and intense, the effects of heat stress on workers' health and productivity.

Health Impacts

- Hospital Admissions: Between 2012 and 2022, 9,119 hospitalisations were caused by extreme weather injuries in Australia, of which 78% (7,104) were caused by extreme heat.

- Excess Deaths During Heatwaves: Heat is responsible for more deaths in Australia than any other natural disaster. Major heatwaves have caused significant loss of life in Australia. The 2009 Victoria heatwave led to 374 excess deaths, while another in 2014 caused 167 deaths.

- Increased Incidence of heat-related illness: Extreme heat can cause dehydration, heat cramps, heat exhaustion, and worsen existing conditions like heart and lung diseases.

Productivity Impact

- Decreased Work Capacity: High heat can make workers tired, unfocused, and irritable, reducing their performance and productivity.

- Increased Risk of Workplace Accidents: Heat stress is associated with a higher likelihood of workplace accidents due to impaired judgment and reduced alertness.

- Economic Costs: Heat stress is estimated to cost the Australian economy around AUD 6.9 billion annually in lost productivity.

Developing a Heat Stress Management Plan

Employers need to implement preventative measures like a heat stress management plan to manage heat stress effectively in the workplace. Here are the key steps to develop a strategy:

1. Identify Heat Hazards

The first and most crucial step in developing effective heat stress management strategies is to identify heat hazards in the work environment. A thorough assessment helps pinpoint areas, tasks, and conditions that pose risks, allowing for targeted interventions. Below is detailed guidance on how to systematically identify heat hazards.

a. Evaluate Environmental Conditions: Start with a comprehensive assessment of the workplace's physical environment to understand how heat might affect employees, such as:

- Temperature

- Humidity

- Heat Index or WBGT Monitoring

- Direct Sunlight

- Lack of Air Movement

Tip: Perform these evaluations at different times of the day, as conditions (like peak afternoon heat) may vary significantly.

b. Identify Specific Tasks or Roles That Pose Risks: Pinpoint high-risk tasks by considering the following factors:

- Outdoor Tasks: Examples include construction work, landscaping, farming, or utility repairs.

- Indoor Tasks: Factory workers using heavy machinery or boilers face significant heat exposure. Tasks in unventilated areas like attics, basements, or tunnels are also high risk.

- Physical Exertion: Jobs requiring heavy lifting, pulling, or prolonged physical activity (e.g., loading/unloading goods, assembling equipment)

c. Assess the Impact of Machinery and Equipment: Machinery and equipment can be critical sources of heat exposure in the workplace.

- Heat-Producing Equipment: Examples include furnaces, ovens, boilers, and hot metalworking tools.

- Motorised Equipment and Vehicles: Possible examples are workers inside non-air-conditioned trucks, forklifts, or other enclosed vehicles

- Protective Gear: Heavy or sealed PPE (like hazmat suits)

Tip: Map out machinery or equipment that radiates heat and determine proximity to employees for an accurate risk profile.

d. Analyse Workplace Layout and Conditions: Are there:

- Confined or Closed Spaces like storage rooms, crawlspaces, equipment closets, tunnels, or basements

- Shaded vs. Open Areas: such as open construction sites or uncovered parking lots.

- Workstations Near Heat Sources

e. Utilise Heat Assessment Tools: Effective identification of heat hazards relies on proper tools and techniques such as:

- Heat Index Charts

- Wet Bulb Globe Temperature (WBGT) Monitors

- Infrared Thermometers

- Environmental Sensors

2. Assess Risk Levels

After identifying heat hazards, evaluate each risk's severity level to prioritise and develop a proper response. Consider the following factors:

- How often are environmental conditions hazardous? How long do employees work in them?

- Are some tasks inherently more strenuous than others?

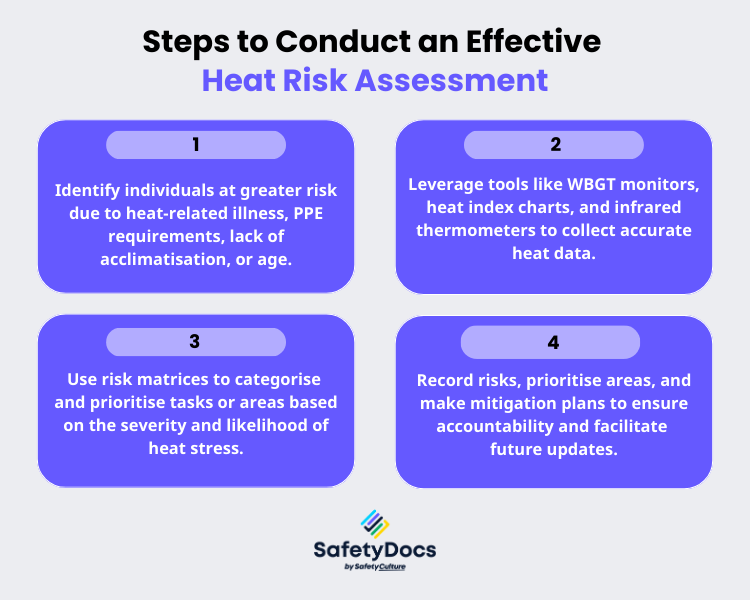

Follow these steps to conduct an effective heat risk assessment:

- Identify individuals at greater risk due to heat-related illness, PPE requirements, lack of acclimatisation, or age.

- Leverage tools like WBGT monitors, heat index charts, and infrared thermometers to collect accurate heat data.

- Use risk matrices to categorise and prioritise tasks or areas based on the severity and likelihood of heat stress.

- Record risks, prioritise areas, and make mitigation plans to ensure accountability and facilitate future updates.

3. Implement Control Measures

After identifying significant sources of heat exposure and assessing risks appropriately, employers should include control measures, such as:

a. Engineering Controls: safety measures designed to eliminate or reduce hazards at their source by modifying equipment, processes, or the work environment.

- Cooling Systems

- Ventilation Improvements

- Shade and Coverings

- Radiant Heat Barriers

b. Administrative Controls: Workplace policies, procedures, and guidelines that minimise heat exposure risks.

- Work-Rest Cycles

- Scheduling Adjustments

- Job Rotation

- Hydration and Cooling Stations

- Acclimatisation Programs

c. Personal Protective Equipment (PPE): Clothing and gear specifically designed to protect employees against extreme heat risks and exposure to hot air. Examples include:

- Headgear or Cooling Vests with Built-in Fans

- UV Blocking Sunglasses

- Cooling Apparel

- Protective Hats

- Breathable Clothing

- Specialised PPE for High-Heat Environments

4. Train Employees

Heat stress management must also include employee training. Without educating employees on heat stress risks, symptoms, and preventive measures, the effectiveness is limited. Training should include:

- Heat illness warning signs

- First aid procedures for heat emergencies

- Proper use of cooling equipment

- The importance of drinking enough fluids and taking frequent breaks during work activities

Tips For Effective Employee Training

Schedule regular heat stress training sessions

- Begin refresher training during hot weather periods or before large outdoor projects.

- Conduct hands-on workshops where employees can practice using cooling devices or responding to heat stress scenarios.

Use visual aids and informational materials to reinforce learning

- Place visual reminders around the workplace, such as infographics showing symptoms and preventive measures.

- Share videos, slideshows, or apps demonstrating heat stress prevention techniques to workers on the go.

Perform emergency response drills.

- Practice responding to mock situations, such as a coworker showing signs of heat stroke.

- Assign responsibilities to team members, such as first responders trained in CPR or supervisors monitoring worker conditions.

5. Monitor and Review Your Strategies

Creating heat stress management controls is just the beginning; maintaining their effectiveness requires ongoing monitoring and regular reviews. Here's how to effectively monitor and review your controls.

- Use tools and methods in data collection, like:

- Temperature Logs

- Worker Health Surveys

- Incident Reports

- Incorporate worker feedback using:

- Surveys/Questionnaires

- Open Forums

- Anonymous Reports

- Adjust the controls as needed based on your findings, for example:

- If surveys indicate workers struggle to stay hydrated, add more water stations or provide electrolyte drinks.

- If reviews show breaks aren't reducing heat stress effectively, revise work-rest cycles or invest in better cooling systems.

- For consistent heat stroke incidents in a specific task, shift this work to cooler times of the day or reduce task intensity.

- Simplify the review process by using templates and checklists.

- Sample of Basic Heat Stress Monitoring Checklist

- Are temperature readings accurately recorded daily?

- Are workers aware of heat stress symptoms?

- Are hydration stations fully stocked and accessible?

- Are rest areas adequately shaded or cooled?

- Have there been any heat-related incidents reported this month?

Is It Mandatory?

In Australia, employers are required under Work Health and Safety (WHS) laws to address health and safety risks from extremes of heat or cold.

Legal Obligations

A Person Conducting a Business or Undertaking (PCBU) must take all practical steps to protect workers from occupational health and safety risks, including those posed by heat stress.

- Risk Management Approach: One way to meet legal obligations is to implement a risk management approach.

Guidelines and Recommendations

No official law requires all industries to have a heat stress management plan. However, Safe Work Australia and state regulators suggest creating heat management plans if extreme heat is a risk at your workplace. The plan should include:

- Risk assessments of heat exposure

- Monitoring of environmental conditions

- Training for workers on recognising symptoms of heat stress

- Procedures for acclimatising workers to hot environments

Failure to effectively manage heat stress risks workers' health and exposes businesses to legal liabilities under Australian WHS laws.

Stay Safe and Compliant with SafetyDocs During the Heat

Is your workplace prepared to handle heat-related risks effectively? SafetyDocs by SafetyCulture provides the tools you need to implement effective heat stress management measures. No matter your industry, we simplify creating safe work procedures while ensuring compliance with WHS laws. Choose from over 200+ templates and customise them to meet your organisational needs.

- Heat Stress Safe Work Method Statement

- Hot Conditions Risk Assessment Form

- Hot Conditions Safety Policy

- Hot Work Permit

Start creating a safer workplace today with SafetyDocs. Contact us to develop your organisation's heat stress management strategies.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article