Earthmoving safety is critical for any excavation, mining, or construction business. Heavy earthmoving equipment presents numerous worker risks that companies must identify and manage to protect their personnel. From excavators to bulldozers, these pieces of machinery can cause serious injury or even death if not handled properly. Employers and employees alike must be aware of their dangers so that they can work safely around them.

What is the Meaning of Earthmoving?

Earthmoving is a part of many construction, mining, and other operations that involve removing and relocating large quantities of soil, rock, or other materials. Various tasks in earthmoving include:

- Creating roads and driveways

- Building foundations for structures

- Digging out rocks for mining activities

- Creating trenches for pipelines

- Digging out deeper corners or slopes from the ground

In earthmoving, using heavy machinery is a common practice. It may include excavators, bulldozers, loaders, graders, and dump trucks. These heavy equipment machines move massive quantities of materials quickly and effectively.

The process of earthmoving is a significant component of a wide range of construction and development projects. Other industries, such as agriculture, land development, and road construction, also benefit from earthmoving activities.

Heavy Equipment For Earthmoving

- Excavators: used for digging, demolition, and material handling. They have a boom, stick, and bucket attachment that can rotate 360 degrees to excavate and move soil, rock, and other materials.

- Bulldozers: used for pushing, grading, and levelling soil and other materials. They have a large, flat blade mounted on the front that can be angled up and down to move and shape material.

- Loaders: These machines are used for moving and loading soil, rock, and other materials into trucks or other equipment. They have a large bucket attachment mounted on the front that can be raised and lowered.

- Graders: are used for grading and levelling soil and other materials. They have a long blade mounted on the underside that can be adjusted to create a smooth, level surface.

- Scrapers: are used for moving large quantities of soil, rock, and other materials over long distances. They have a large, open bowl or hopper that can be lowered to scoop up material and then raised to transport it to a new location.

- Backhoes: are used for digging and excavation. They have a boom, stick, and bucket attachment mounted on the back that can rotate 180 degrees to dig trenches and holes.

- Dump Trucks: These vehicles are used for transporting soil, rock, and other materials over long distances. They have a large, open bed that can be raised to dump the material at the desired location.

Observing proper handling and safety measures when using this equipment is essential. A level of expertise and necessary licences are also required for people handling heavy machinery.

Hazards in Working Around Heavy Equipment

Working with earthmoving equipment is dangerous when proper precautions and safety measures are not in place. Safework Australia reported 142 fatalities in Australia related to earthmoving and construction over five years from 2017-2021. The PCBU (person conducting a business or undertaking) must keep workers and the workplace safe.

Mechanical Hazards

Earthmoving equipment has many moving parts. The movements may have sufficient force in motion to cause injury to people. Machines and equipment can eject objects that may strike a person with force. Mobile equipment, such as forklifts, pallet jacks, and earthmoving equipment, operated in areas where people may gain access are also potential sources of risk.

Here are the common mechanical hazards:

- Struck-by accidents. This can happen when workers are hit by moving equipment or materials such as soil or rocks, which can cause serious injuries or even death. About 11.95 % of accidents in Australia from 2003 to 2014 were from being hit by moving objects.

- Caught-between accidents. Workers can become caught, pinched, crushed, or compressed between two or more objects. Moving earthmoving equipment, or the equipment and a fixed structure such as a wall or pile of materials, can also be dangerous. That said, caught-in and caught-between incidents often result from negligence, improper health and safety procedures, or failure to adhere to safety regulations. It represents 7% of Australia's work-related fatalities.

- Tipping Injuries. This is when a piece of earthmoving equipment becomes unstable or tips over an inclined surface.

Non-mechanical Hazards

Non-mechanical hazards are the most common sources of risks in earthmoving sites. These include slips, trips and falls, noise exposures, unguarded machinery, and material handling.

People exposed to certain dangers may not have any problems for long. But later, they can have hearing loss, breathing troubles, and even cancer. Non-mechanical hazards include the following:

- Electrical Hazards. An electrical risk is a threat to a person's life, safety and well-being that can be caused directly or indirectly by an electric current. Electrical systems in the machinery can malfunction and cause electrocution. It is essential to check the wiring of all electrical equipment before use.

- Slips, Trips, and Falls. Slips and trips can result from wet floors, loose cables, cords, or ground debris. Wear appropriate footwear, use fall protection equipment, and keep all work areas clean to avoid these accidents.

- Noise Exposure. Heavy machinery can be loud and cause hearing damage if not adequately protected. Noise can damage the ability to hear clearly and make it more challenging to listen to the sounds necessary for working safely, such as instructions or warning signals.

- Respiratory Hazards. This may occur when workers are not using proper Personal Protective Equipment (PPE). This may include exposure to hazardous substances, fumes, or other airborne contaminants.

- Fatigue. Operating earthmoving equipment can be physically demanding and may lead to operators' fatigue. When fatigue sets in, the risk of an accident increases significantly.

Access Hazards

Access hazards are associated with entering, exiting, and working at heights using earthmoving equipment. Some risks include falling from equipment or being caught between the machine and an object. For example, a worker entering or exiting an excavator can be seriously injured if he slips or falls from the cabin

Workers should always use appropriate ladders or steps when entering and exiting a machine. Fall protection equipment (including harnesses) should also be used when working at heights (for example, when accessing the engine of a large excavator).

Major Causes of Accidents in Earthmoving

Aside from the mentioned hazards, there are other causes of accidents in earthmoving projects. These include:

Lack of safe systems for earthmoving operations

Safe systems help identify, assess, and control risks associated with operating heavy earthmoving equipment. Workers may be exposed to health and safety risks without a secure work system. These may include using safety documents, conducting safety inspections, performing risk assessments, and using personal protective equipment.

Negligence in the proper selection and use of equipment

Earthmoving equipment must be selected and used appropriately and safely. Improper selection or use of the equipment can lead to accidents and injuries. For example, using equipment unsuitable for the job can result in an injury due to malfunction or fatigue.

Inadequate training or lack of experience among operators

Operating earthmoving equipment requires significant skill and knowledge to use them safely. Operators must be properly trained and instructed to use the equipment safely. Registration or licensing may be required for certain types of equipment. It is also best to obtain a licence from Safe Work Australia.

Noncompliance with maintenance requirements

Maintaining and servicing heavy earthmoving equipment is critical to ensure the safety of workers. Unmaintained or faulty equipment can malfunction and lead to accidents. You can use inspection checklists and maintenance logs to help keep track of the equipment's condition.

Failure to observe the required earthmoving safety precautions

Workers must know the potential hazards of operating heavy earthmoving equipment and observe required safety precautions. This includes always wearing the appropriate Personal Protective Equipment (PPE), conducting risk assessments, and using safe work method statements.

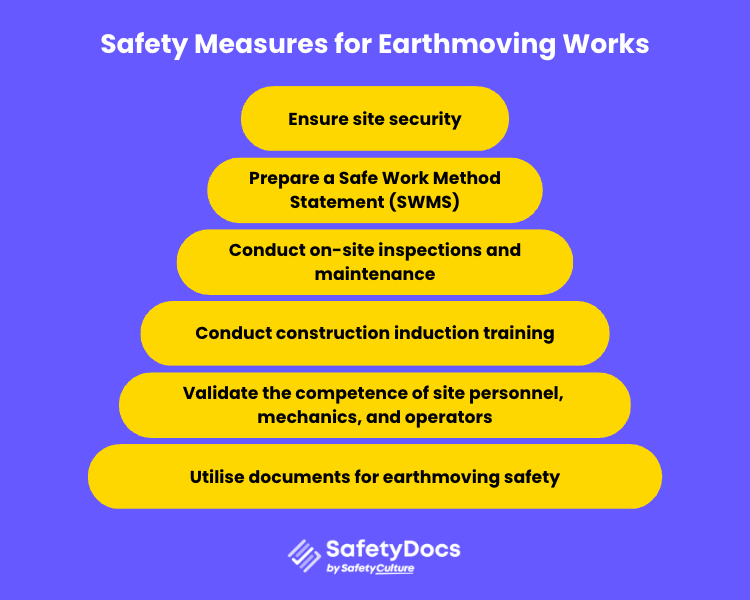

Safety Measures for Earthmoving Works

Employers and contractors bear equal responsibility for ensuring that their workers have access to all pertinent information, instruction, training, and supervision. The construction industry relies heavily on the cooperation and coordination of employers, owners, contractors, site management personnel, mechanics, and operators. This ensures the highest safety and performance standards are met when using heavy earth moving machinery.

Here are safety control measures you can take to ensure a safe and successful earthmoving project:

1. Ensure site security

Restricting site access is insufficient to protect expensive machinery from damage and theft. Implementing a robust security system with alarms, cameras, and access control measures like locks and electronic tagging is essential.

Another reason for site security is to ensure the safety of construction workers and pedestrians before, during, and after work hours. This entails authorised inspections and management of the construction site. It is also essential to cordon off the area with barriers to keep workers from accidentally getting close to operating equipment.

2. Prepare a Safe Work Method Statement (SWMS)

High-risk construction work involves excavation operations such as digging shafts, trenches, or tunnels deeper than 1.5 metres and any operation with a risk of falling over 2 metres. It also includes the potential to collide between mobile-powered plants and people or other machinery.

In order to perform these excavation activities safely and effectively, you must create a mandatory safe work method statement.

Companies can achieve a successful outcome in even the most hazardous conditions with comprehensive planning and checklists.

3. Conduct on-site inspections and maintenance

Adopting a rigorous inspection and maintenance program to ensure the equipment is safe and fit for use is critical. On-site inspections should be carried out regularly, with any faults reported and rectified immediately. This will ensure that workers use the correct equipment and that all safety features are in full effect.

The inspection and maintenance program should include:

- regular oil changes

- fuel top-ups

- checking for leaks or faults

- ensuring all guards are in place

4. Conduct construction induction training

Earthmoving, such as excavation works, is part of construction activities, so all workers must attend a general induction training program. Construction induction training cards, commonly called 'white cards,' are required for workers on all construction sites across Australia.

Workers must be able to demonstrate the card upon request from the PCBU on-site and any inspectors. The 'Prepare to Work Safely in the Construction Industry' course, also known as 'white card' training, is essential to gain a white card.

5. Validate the competence of site personnel, mechanics, and operators

In Australia, the legal requirement for licences for earthmoving machinery is governed by each state and territory's workplace health and safety regulator. Generally, operating certain types of earthmoving machinery requires the operator to hold a specific licence or competency certificate.

It is important to note that the requirements for licences or competency certificates can vary depending on the type of equipment, the jurisdiction, and the specific workplace. Therefore, individuals and organisations must familiarise themselves with the relevant legislation and regulations applicable to their circumstances.

6. Utilise documents for earthmoving safety

Safety documents are vital to managing health and safety on the worksite. They provide a roadmap for safe operations, detailing expectations for workers and employers alike. Here are some safety documents from SafetyDocs that provide comprehensive guides on different aspects of earthmoving practices:

- Earthmoving and Mobile Plant SWMS: This document covers the safe use of mobile plant, preventing falls from height and protecting workers from moving parts.

- Integrated Management System (IMS) for Earthworks: This IMS provides the framework needed to develop and maintain a safe operation tailored to the needs of companies with earthmoving projects. This manual ensures that safety standards surrounding heavy vehicle use are met.

- Plant Risk Assessment Form: This Plant Risk Assessment Form is an essential tool to help ensure the highest level of safety when examining and operating an earthmoving plant. It allows you to identify potential hazards and safely control them with preventative measures.

- Emergency Response Plans: Earthmoving operations can be dangerous and unpredictable, making an emergency response plan crucial. This document outlines critical steps to take in the event of a significant incident that could lead to severe injury or even death.

- Plant Attachment Maintenance Safe Operating Procedure: This document outlines the guidelines for ensuring that plant attachments are safely operated and maintained.

Stay Safe While Working with Heavy Equipment Using SafetyDocs

To ensure that your earthmoving operations are safe and compliant with safety legislation, SafetyDocs by SafetyCulture offers documents to help you protect personnel and the work site. Our customisable templates will help simplify safety practices and ensure your personnel work confidently and safely.

Our content-rich solutions are easy to use and 2023-compliant. Find the right safety, environmental, or quality documents for your workplace. Use SafetyDocs to transform your work processes to save time and lives. Contact us to learn more.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article