This is the third in a four-part series on building a comprehensive workplace safety system.

The Gold Standard for Managing Risk

In Weeks 1 and 2, you learned how to identify hazards and assess their risks. Now, you’re ready for the most important part of the safety process: controlling those risks. But how do you choose the right control measure?

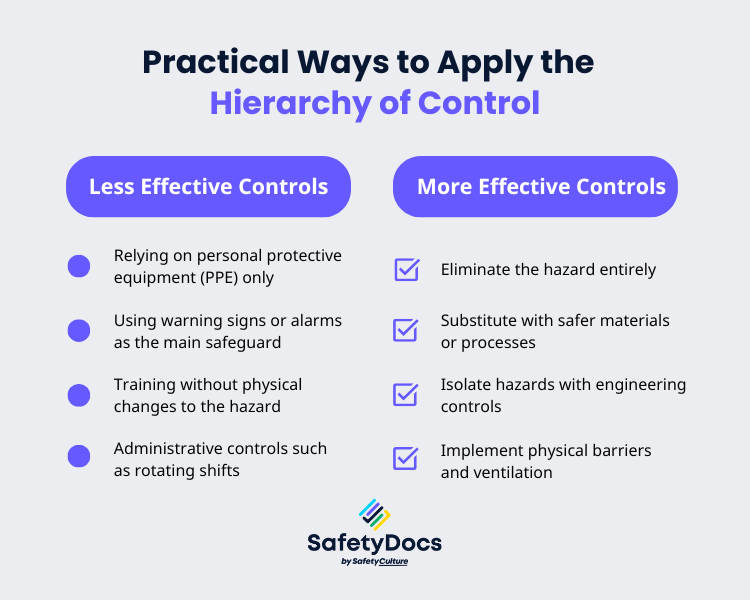

Under Australia's Work Health and Safety (WHS) Act, businesses have a duty to eliminate or minimise risks as far as is reasonably practicable. To help with this, Safe Work Australia has established the Hierarchy of Controls, which is the internationally recognised gold standard for managing workplace risks.

This hierarchy is a step-by-step guide, ranked from the most effective control measures to the least effective. By following it, you can ensure you’re choosing the best possible solution, rather than just the easiest one.

The Five Levels of Control

Think of the hierarchy as a pyramid. Your goal is always to move as far up the pyramid as possible.

Level 1: Elimination (Most Effective)

Elimination means completely removing the hazard from the workplace. If you can eliminate the hazard, the risk is gone forever. This is the most effective control because it provides the highest level of protection.

How to Do It:

- Replace a toxic cleaning chemical with a non-toxic alternative.

- Use a contractor to handle a dangerous task like working at height or in a confined space.

- Stop a specific, high-risk process altogether.

Example:

- Instead of having workers manually lift heavy materials, you eliminate the hazard by installing a forklift or a crane. The need for manual lifting is gone, and so is the risk of back injury.

Level 2: Substitution

Substitution involves replacing a hazardous material or process with a safer one. It doesn’t eliminate the hazard, but it reduces the risk.

How to Do It:

- Replace a solvent-based paint with a water-based one.

- Use a pre-fabricated structure instead of constructing one on-site, which reduces the need for dangerous cutting and welding.

- Swap out a noisy machine for a quieter model.

Example:

- A bakery owner substitutes flour with a low-dust alternative to reduce the risk of a worker developing asthma from prolonged inhalation.

Level 3: Engineering Controls

Engineering controls are physical changes to the workplace, equipment, or process that reduce the risk. These are a strong, reliable form of control because they don’t rely on a person remembering to do something.

How to Do It:

- Install guards on moving machinery parts.

- Use local exhaust ventilation to remove chemical fumes.

- Install a safety rail or fall arrest system on a roof.

Example:

- A workshop installs a ventilation system to extract welding fumes at the source, preventing them from spreading into the air and being inhaled by workers.

Level 4: Administrative Controls

Administrative controls are changes to the way people work. This includes procedures, rules, training, and signs. These are less effective than the controls above because they depend on human behaviour.

How to Do It:

- Develop a new Safe Work Method Statement (SWMS) for a high-risk task.

- Implement a roster that limits a worker's time in a noisy area.

- Put up signs warning of a hazard (e.g., "CAUTION: Hot Surface").

Example:

- A company creates a formal lifting procedure and provides training to all staff to reduce the risk of back injuries.

Level 5: Personal Protective Equipment (PPE) (Least Effective)

PPE is a last resort. It's equipment worn by the worker to protect them from a hazard. It is the least effective control because it only protects the individual and does not reduce or eliminate the hazard itself. It also relies on the worker using it correctly, every time.

How to Do It:

- Provide hearing protection like earmuffs in noisy areas.

- Supply safety glasses to protect from flying debris.

- Require steel-toed boots in a construction area.

Example:

- A worker wears safety gloves to protect their hands from chemicals when there is no other practical way to eliminate or substitute the substance.

The Importance of Combining Controls

In many workplaces, a single control measure isn't enough. To achieve a safe outcome, it's often necessary to combine controls from different levels of the hierarchy. For example, a worker might be required to use a quieter machine (Substitution) with an attached safety guard (Engineering), follow a Safe Work Method Statement (Administrative), and wear gloves (PPE).

By using the Hierarchy of Controls, you’re not just meeting your legal obligations; you’re making a real, tangible difference to the safety and well-being of your entire team.

Frequently Asked Questions

Q: Why is PPE the last resort? PPE is the last resort because it is the least reliable control. It can be uncomfortable, improperly fitted, or simply not used, meaning the hazard still exists and can cause harm.

Q: What is the difference between an engineering and an administrative control? An engineering control is a physical modification to the workplace or equipment (e.g., a machine guard). An administrative control is a change in a procedure or a rule (e.g., a safety sign or a training program).

Q: Do I have to use the Hierarchy of Controls? Yes. Under the WHS Act, you must follow the hierarchy and try to eliminate the risk first. If that's not reasonably practicable, you move down the hierarchy.

Q: Can I just use PPE? No. You cannot rely on PPE alone. You must first try to use a higher-level control from the hierarchy and only use PPE as a supporting measure or where no other control is practical.

Take Action with our Free Safety Essentials Checklist SafetyDocs by SafetyCulture

You've identified your hazards, assessed your risks, and now you know how to choose the right controls. The next step is to put your plan into action and make it official. Our Control Measures Register (included in our National Safe Work Month Safety Essentials Pack) is the perfect tool for this. It provides a structured way to track your decisions, assign responsibility, and ensure all your controls are implemented on time.

Click here to download the pack and take control of your safety system.

Looking to take the next step in your safety journey? Our team of specialists can help. Whether you need more information, tailored policies, or complete safety management systems, we’re here to help you protect your business. Contact our Customer Care Specialists to learn more about our full suite of professional resources.

Author - Craig Cruickshank is the HSEQ Manager and Senior Technical Advisor at SafetyDocs by SafetyCulture.

Craig comes from a construction and environmental background, with experience in both the private and public sectors and is passionate about making health and safety information easy to find and understand for everyone.

Learn more about Craig's work on LinkedIn

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article