Jul 15th 2025 |

Safe Work Method Statements (SWMS) vs Job Safety Analysis (JSA): What's the Difference?

In high-risk industries, clear and effective safety documentation is non-negotiable. But for many businesses, the difference between a Safe Work Method Statement (SWMS) and a Job Safety Analysis (JSA) can be confusing. While both tools support workplace safety compliance, they are not interchangeable, and using the wrong one could lead to compliance issues or overlooked hazards.

In this guide, we are going to break down the differences between SWMS and JSA, explain when to use each, and share how both documents support better hazard identification, risk assessment, and overall safety planning.

What is a Safe Work Method Statement?

A Safe Work Method Statement (SWMS) is a structured document that outlines how to carry out high-risk work safely. It identifies the hazards associated with a specific task, assesses the risks, and details the control measures that must be implemented to protect workers and others on site. Under Australian WHS laws, a SWMS is legally required for high-risk construction work, but its use has become widespread across various industries as a best-practice approach to managing dangerous tasks.

The primary purpose of a SWMS is to help businesses and workers systematically manage risk by providing a step-by-step safety plan for hazardous activities.

When is a SWMS Legally Required?

According to Safe Work Australia, a SWMS is needed for all high-risk construction work (HRCW). This includes activities such as:

- Working at heights over 2 metres

- Working near live electrical services

- Demolition work

- Use of explosives

- Confined space entry

Failing to prepare a compliant SWMS for such activities can expose a business to legal penalties, regulatory action, and increased risk of workplace incidents.

Can SWMS Be Used Outside of Construction?

Yes, while SWMS are a legal requirement only for high-risk construction work, they are widely adopted across many sectors as a risk management tool. Organisations in manufacturing, mining, utilities, maintenance, and even landscaping use SWMS or SWMS-style documentation to manage potentially hazardous tasks.

Examples of high-risk activities where a SWMS may be used, include:

Adopting SWMS outside of construction demonstrates a strong safety culture and can significantly reduce the likelihood of serious incidents or regulatory non-compliance.

What Does a SWMS Include?

A well-prepared SWMS should be clear, site-specific, and developed in consultation with the workers involved. Key elements include:

- A detailed description of the high-risk work being performed

- Identification of hazards and associated risks

- Control measures based on the hierarchy of controls

- A sequence of steps for safely completing the work

- Roles, responsibilities, and communication protocols

- Monitoring and review procedures to ensure controls remain effective

By clearly outlining how work should be carried out, a SWMS ensures everyone understands the risks, and the actions required to stay safe.

Why Use SWMS as Part of Your Safety Planning?

Even when not legally required, SWMS are a valuable tool for reinforcing safe behaviours, supporting workplace safety compliance, and engaging workers in the hazard identification and risk assessment process.

Whether you're managing a demolition project, cleaning confined spaces, or working near powerlines, having a clear, structured plan in place protects both people and business operations.

Need a professional, ready-to-use SWMS? Explore the full range of Safe Work Method Statement (SWMS) Templates to meet your legal and safety planning needs.

What is a Job Safety Analysis?

A Job Safety Analysis (JSA), also known as a Job Hazard Analysis (JHA) or Job Safety and Environmental Analysis (JSEA), is a structured process used to assess the safety risks of a specific task before work begins. Unlike a SWMS, which is required by law for high-risk construction work, a JSA is a best-practice safety planning tool with broad application across many industries and job types.

The purpose of a JSA is to proactively identify hazards, evaluate potential risks, and determine the safest way to perform a job by applying effective control measures. It helps workers and supervisors break down a task into its individual steps, spot what could go wrong, and plan accordingly.

Key Features of a JSA

A well-developed JSA:

- Breaks down a job or task into clear, logical steps

- Identifies potential hazards at each step

- Recommends risk control measures to eliminate or reduce those hazards

- Documents safe procedures and work practices

- Encourages consultation and active involvement from workers

By involving the people who actually perform the task, JSAs promote ownership and a stronger safety culture, a vital part of preventing workplace incidents before they happen.

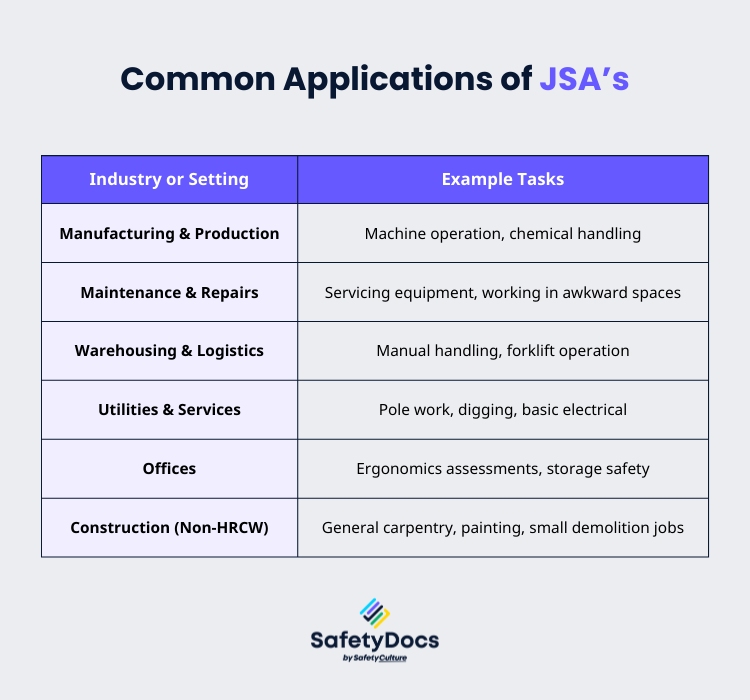

Where is a JSA Used?

While JSAs are not usually required by law, they are commonly used across industries where safety risks need to be managed, even if the task isn’t considered “high-risk” under WHS legislation. They’re ideal for routine tasks, one-off jobs, or any activity where hazards are present but not covered by a SWMS.

Because of their flexibility, JSAs are a valuable addition to any safety system, even in administrative environments.

Why Use a JSA?

JSAs are not just paperwork; they’re a practical tool that can help you:

- Reduce injuries and near-misses by identifying risks early

- Communicate safe work procedures clearly to your team

- Improve consistency and accountability in safety practices

- Involve workers in meaningful hazard identification and risk assessment

- Train new staff on job-specific safety considerations

They are particularly effective for non-high-risk work where a full SWMS isn’t required but planning is still crucial.

Want to save time without sacrificing safety? Use a fully editable JSEA Template to get started quickly and standardise your process across worksites.

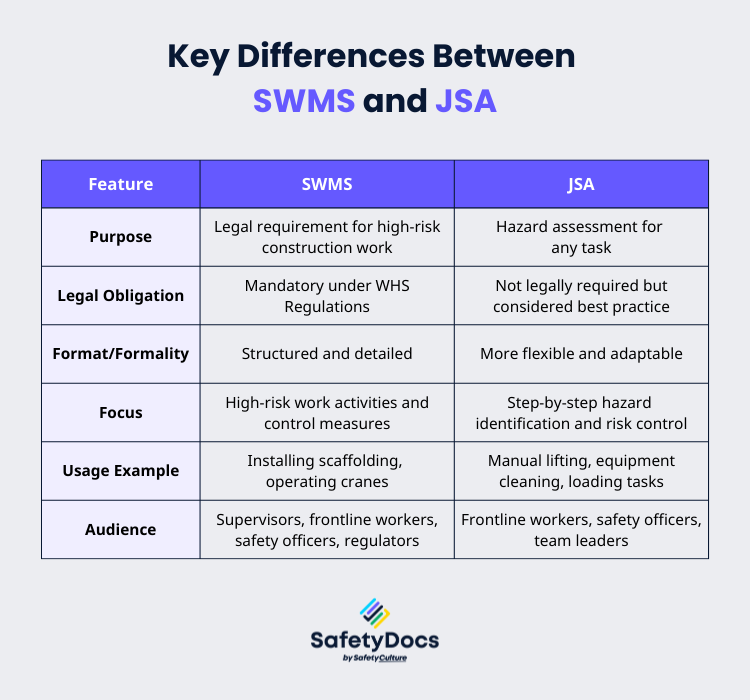

Key Differences Between SWMS and JSA

While both documents contribute to safer worksites, they serve different purposes and carry different legal and operational weight. Here's a side-by-side look at the SWMS vs JSA comparison:

Understanding these key differences allows businesses to use each document appropriately, ensuring they’re not only compliant but also making informed decisions to manage risks effectively.

When to Use SWMS vs JSA

Knowing when to use a SWMS or JSA can make a big difference in maintaining workplace safety compliance and ensuring that risks are managed effectively. While both tools help reduce incidents, they’re used in different contexts and serve different operational needs.

When to Use a SWMS

As mentioned, a SWMS is required whenever high-risk construction work is being carried out as defined under WHS Regulations. This includes tasks where the potential for serious injury is significant.

Use a SWMS when:

- You are performing any High-Risk Construction Work, such as:

- Working at heights (e.g. roof installation, scaffolding)

- Trenching and excavation

- Asbestos removal

- Working near live electrical installations

- Demolition activities

- The work is routine, ongoing, or legally regulated, and you need a formal, site-specific safety document

- You need to demonstrate compliance to principal contractors, auditors, or regulators

- The job forms part of a broader project where safety documentation is a contractual requirement

Example:

A roofing contractor must prepare a SWMS that outlines fall prevention measures, use of harnesses, and emergency procedures when working at heights over 2 metres.

When to Use a JSA

Remember that a JSA is ideal for tasks that are not legally defined as high-risk construction work, but where hazards still need to be controlled. JSAs are commonly used across industries beyond construction, offering a more flexible and collaborative approach to safety planning.

Use a JSA when:

- Performing a task that’s non-routine, unfamiliar, or without an existing Safe Operating Procedure (SOP)

- Engaging workers in hazard identification and control before starting a job

- Conducting work in a range of industries, including:

- Manufacturing: Equipment cleaning, machine maintenance

- Mining: Spot excavation or drilling

- Utilities: Basic electrical servicing or confined space entry

- Landscaping: Chainsaw operation or work near roads

- Warehousing: Manual lifting, use of trolleys or pallet jacks

- You need a simple and effective tool to communicate safe work procedures to frontline staff

Example:

A warehouse supervisor asks their team to complete a JSA before moving heavy pallets. The team breaks down the task into steps, identifies potential hazards like slips or strain injuries, and applies controls like team lifting and PPE.

Can You Use Both?

Yes. In many cases, a SWMS and JSA can work together. For example:

- A project may require a SWMS to address legal compliance for the overall high-risk task (e.g. working at heights),

- While a JSA is used to assess individual components of that job, like the setup of ladders or manual handling of materials.

This layered approach can strengthen your safety systems and help ensure that risks are assessed at both macro and micro levels.

SWMS vs JSA: Use the Right Tool, Use SafetyDocs for the Job

The differences between SWMS and JSA matter. Understanding when to use SWMS or JSA can be the difference between meeting your safety compliance obligations and falling short. While Safe Work Method Statements are essential for legally mandated high-risk activities, Job Safety Analyses offer broader value across routine tasks and day-to-day safety planning.

Using both correctly helps embed hazard identification, risk assessment, and ongoing safety conversations into your worksite, leading to better outcomes for your business and your people.

Make It Easy with SafetyDocs

Creating safety documents from scratch takes time and can leave room for error. SafetyDocs by SafetyCulture makes it simple to implement effective safety planning through professional, fully editable templates that are aligned with WHS laws and industry best practices.

- Safe Work Method Statement (SWMS) Templates: Designed for compliance with WHS Regulation requirements, ideal for high-risk construction work.

- JSEA Template: Streamlined, practical, and easy to customise for any job or industry.

Need help with broader risk controls? Check out our full suite of risk management templates and Risk Management Plans to support a safer, more compliant workplace.

Take the guesswork out of compliance, choose SafetyDocs by SafetyCulture for WHS documents you can trust. Contact us today for expert advice on improving your WHS audits.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article