This is the first of a four-part series on building a comprehensive workplace safety system.

The Proactive Approach to Workplace Safety

Every year, thousands of workers are injured or become ill on the job. The vast majority of these incidents were preventable. The key to a truly safe workplace isn't just reacting to accidents after they've happened, but proactively finding and controlling the dangers before they can cause harm. This process is known as hazard identification, and it's the first and most crucial step in effective safety management.

A hazard is anything with the potential to cause harm. It can be obvious, like a live electrical wire, or it can be a subtle risk you might not even see, like a stressful work environment that leads to burnout. Identifying these hazards is a legal requirement under Australia's Work Health and Safety (WHS) Act, but more importantly, it's a fundamental responsibility for any business owner committed to protecting their team.

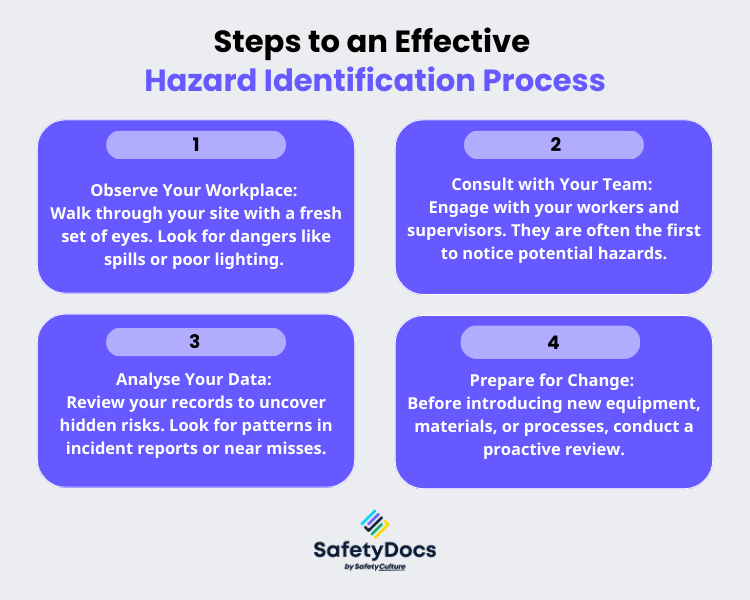

Your Four-Step Guide to Proactive Hazard Identification

Proactive hazard identification is not a one-time event; it's a continuous process. By following these four simple steps, you can create a systematic approach that makes your workplace safer every day.

1. Walk Around and Observe

This is the most common and effective method for finding hazards. Regularly walking through your workplace with a fresh set of eyes allows you to spot dangers in their natural environment. But don't just wander around; be systematic. Use a hazard identification checklist - like the one included in our FREE Safety Essentials Pack - to guide your observations. A good checklist will help you be thorough and ensure you don’t miss anything.

What to Look For:

- Physical Hazards: Are walkways clear of clutter? Are fire exits blocked? Is there exposed wiring or are cords a tripping hazard? Is the lighting adequate?

- Equipment Hazards: Is machinery guarded correctly? Are emergency stops easily accessible? Is equipment being used for its intended purpose?

- Chemical Hazards: Are hazardous substances clearly labelled? Is proper storage being used? Are there any spills, leaks, or strong odours?

- Noise and Vibration: Is the noise from machinery or tools at a level that could cause hearing damage over time?

- Environmental Factors: Are temperatures too hot or cold? Is there adequate ventilation? Is there mould or a buildup of dust?

2. Talk to Your Team: The Power of Consultation

Your employees are your most valuable resource in hazard identification. They are on the front lines every day and are often the first to notice a potential hazard or a safer way of doing a task.

The WHS Act requires businesses to consult with their workers on health and safety matters. But this isn't just a legal obligation; it's a strategic advantage. When workers feel heard, they are more likely to report issues, suggest improvements, and take ownership of safety.

How to Encourage Consultation:

- Hold Regular Safety Meetings: Dedicate time in team meetings to discuss safety issues and concerns.

- Provide a Feedback Channel: Create a confidential suggestion box, a simple online form, or encourage one-on-one chats.

- Conduct Safety Discussions: Ask your team direct questions like, "What is the most difficult or risky part of your job?" or "Is there any equipment that is frustrating or hard to use?"

3. Review Your Data to Find Hidden Patterns

Safety data is not just about incident reporting; it's a goldmine of information waiting to be analysed. By reviewing your records, you can uncover recurring themes that point to underlying system issues.

What to Review:

- Incident Reports: Look at what happened, but also why it happened. Was it a lack of training, a faulty piece of equipment, or a procedural issue?

- Near-Miss Reports: These are invaluable. A near-miss is a warning sign that a hazard exists. A near-miss today could be a serious injury tomorrow. Encourage reporting these incidents as a key part of your safety culture.

- First-Aid Logs: A high number of minor injuries like cuts, scrapes, or back strains can indicate a repetitive task hazard or a poor manual handling procedure.

- Maintenance Logs: Are certain machines or tools requiring more frequent repairs? This could signal a hidden safety issue.

4. Be Proactive with Change: Hazard Identification for New Processes

Every time you introduce new equipment, materials, or change a process, new hazards can arise. Taking a proactive approach before implementing any changes is far more effective than trying to fix problems after they happen. This is a crucial step for preventing incidents.

Before implementing a change, take the time to conduct a Job Safety Analysis (JSA) or a specific hazard identification review. This process helps you ask the right questions:

- How will this new process affect a worker's body? (Ergonomics)

- What new chemicals or substances are being introduced?

- Does the new equipment have appropriate safety guards?

- Are workers trained and competent to use the new tools?

What to Do After You Find a Hazard

Once you've identified a hazard, your work isn't done. The next step is to assess the risk associated with that hazard. This is where you determine the likelihood of harm and the potential severity of that harm. This is the focus of our next blog post in Week 2.

Frequently Asked Questions

Q: What is the difference between a hazard and a risk? A hazard is the potential for harm (e.g., a loose step). A risk is the likelihood that a hazard will cause harm and the severity of that harm (e.g., the high risk of a serious fall due to the loose step on a busy staircase).

Q: How often should I do a hazard walkaround? You should conduct formal walkarounds on a regular schedule (e.g., monthly or quarterly) but also constantly, informally check for hazards every day.

Q: Who is responsible for identifying hazards? Under the WHS Act, every person in the workplace has a duty of care. The business owner (PCBU) has the primary duty, but workers are also responsible for taking care of their own safety and the safety of others, and for reporting hazards.

Get a Head Start with our Free Safety Essentials Checklist from SafetyDocs by SafetyCulture

Identifying hazards is the first step toward a safer, more compliant business. But you don't have to start from scratch. Our Hazard Identification Checklist (included in our National Safe Work Month Safety Essentials Pack) is a free, ready-to-use tool that guides you through the process, ensuring you don't miss a thing.

Click here to download the pack and take the first step toward building a proactive safety system.

Looking to take the next step in your safety journey? Our team of specialists can help. Whether you need more information, tailored policies, or complete safety management systems, we’re here to help you protect your business

Contact our Customer Care Specialists to learn more about our full suite of professional resources.

Author - Craig Cruickshank is the HSEQ Manager and Senior Technical Advisor at SafetyDocs by SafetyCulture.

Craig comes from a construction and environmental background, with experience in both the private and public sectors and is passionate about making health and safety information easy to find and understand for everyone.

Learn more about Craig's work on LinkedIn

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article