On busy worksites, safety conversations need to be quick, clear, and memorable. That’s where toolbox talks come in.

A toolbox talk, sometimes called a pre-start or safety talk, is a short, informal meeting that focuses on one safety topic. Done well, they’re one of the most powerful ways to reinforce safe behaviour and open two-way WHS communication. Done poorly, they become a tick-the-box exercise that workers tune out.

In this guide, we’ll explain why toolbox talks matter, highlight common pitfalls, and show you step-by-step how to run a safety talk that actually works.

What Are Toolbox Talks?

Toolbox talks, also known as safety talks or safety briefings, are short, informal meetings held in the workplace to discuss health and safety risks, review safety procedures, and promote safety awareness among employees. These essential conversations focus on identifying potential hazards, reinforcing safety protocols, and ensuring everyone understands emergency procedures.

By regularly discussing relevant safety topics, toolbox talks help prevent accidents and create a safer work environment. They also provide a valuable opportunity for employees to raise concerns, share experiences, and discuss ways to improve health and safety across the workplace. As an essential part of any safety program, toolbox talks keep safety top of mind and encourage open dialogue about risks and safe work practices.

Why Toolbox Talks Matter

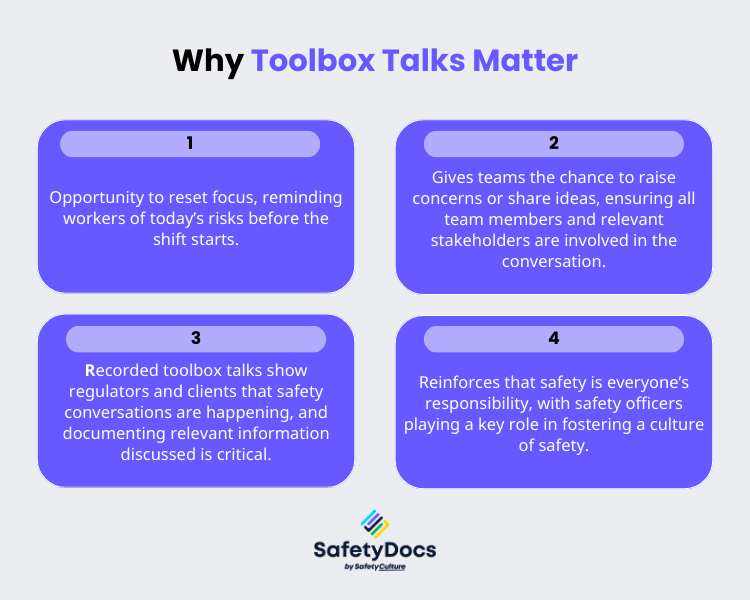

Toolbox talks are more than quick chats before starting work. They are essential for creating a safe work environment and protecting the business and its workers. They are:

- Opportunities to reset focus - reminding workers of today’s risks before the shift starts.

- Moments for engagement - giving teams the chance to raise concerns or share ideas, ensuring all team members and relevant stakeholders are involved in the conversation.

- Proof of compliance - recorded toolbox talks show regulators and clients that safety conversations are happening, and documenting relevant information discussed is important for both safety officers and business compliance.

- Culture of safety - reinforcing that safety is everyone’s responsibility, with safety officers playing a key role in fostering a culture of safety.

A five-minute talk can prevent a serious incident if it addresses the right hazard at the right time. Sharing relevant information during toolbox talks ensures everyone is informed and engaged.

What Makes a Toolbox Talk Effective?

The most effective toolbox talks share a few qualities:

- Relevance - linked to current site hazards, recent incidents, or seasonal risks.

- Interaction - encouraging workers to share experiences, ask questions, or suggest solutions, and ensuring every worker has a reasonable opportunity to participate and share their perspectives.

- Consistency - run regularly, so safety conversations become a habit.

- Brevity - short and sharp, ideally 5-10 minutes.

When safety talks are practical, engaging, and concise, workers pay attention and retain the message.

Common Health and Safety Risks and Pitfalls to Avoid

Unfortunately, toolbox talks often fail because they’re treated as admin, not a safety conversation. The most common mistakes include:

- Ticking the box - rushing through the talk to “get it done” without meaning.

- Low engagement - one-way delivery where the supervisor reads from a sheet and no one participates. Failing to encourage workers to provide feedback can lead to missed safety issues and lower participation.

- Repetition without relevance - covering the same topics again and again until crews switch off.

- Poor timing - long talks at the wrong time of day, when workers are distracted or tired.

Avoid these traps, and your toolbox talks will feel less like a chore and more like a useful safety tool.

Step-by-Step: How to Run a Toolbox Talk

It is important to conduct safety talks regularly to maintain safety awareness and compliance. Follow these steps to make your talks effective:

1. Choose a Timely Topic

Base the talk on what’s happening now:

- A recent incident or near miss.

- Specific site hazards (e.g. scaffolding, traffic management).

- Toolbox talks focused on a specific task or high-risk activity relevant to the day's work.

- Seasonal risks (heat stress in summer, slips in winter).

2. Keep It Short, Sharp, and Focused

A toolbox talk should run for 5–10 minutes max. Stay focused on one clear theme. Long-winded talks lose attention and impact.

3. Use Real Examples and Visual Aids

Bring the topic to life with:

- Photos from your site.

- Demonstrations with equipment.

- Real incidents (without blame).

- Examples showing the correct use of hard hats as essential PPE, including how they protect against head injuries and comply with safety standards.

Visuals and stories stick far better than abstract rules.

4. Encourage Questions and Input

Don’t just talk, ask. Invite workers to share experiences or raise issues. Questions like:

- “What risks do you see today?”

- “Has anyone had a close call with this hazard before?”

Supervisors or safety officers should also advise workers on best practices and hazard controls during the discussion. Engagement turns passive listeners into active problem-solvers.

5. Document Attendance

Use a Toolbox Talk Record Form to capture details of each toolbox meeting, including the topic covered, names of attendees, and actions required. This not only proves compliance but also helps follow up later.

6. Follow Up on Actions

If hazards or issues come up during the talk, follow through. Record them, assign responsibility, and provide updates at the next meeting. This shows workers their input matters.

Best Practices for Toolbox Talks

Toolbox meetings are a best practice in many workplaces to promote safety and compliance. Beyond the basics, here are some tips to keep toolbox talks fresh and effective:

- Rotate speakers - encourage different team leaders or even workers to run the toolbox meetings. Rotating leadership in toolbox meetings boosts engagement.

- Prepare in advance - choose a topic and gather visuals before the talk. Avoid winging it.

- Mix up locations - sometimes hold the talk by the equipment in question, or where the hazard exists.

- Be conversational - drop the jargon and speak plainly. Workers respond better to real language.

- Connect to the bigger picture - link the topic back to why it matters for everyone’s safety and compliance.

Overcoming Challenges and Barriers

Running effective toolbox talks isn’t always easy, especially in high-risk industries where hazards are more frequent and time is tight. Common barriers include limited time, stretched resources, and difficulty engaging employees who may see safety meetings as just another task.

To overcome these challenges, health and safety representatives and safety officers can get creative: use real-life examples from the workplace, bring in visual aids, and actively involve employees in the discussion.

By making toolbox talks interactive and relevant, you can boost safety awareness, reduce workplace incidents, and ensure compliance with health and safety regulations. Involving employees in these conversations not only helps identify risks but also builds a stronger safety culture where everyone feels responsible for workplace safety.

The Role of Training and Development

Training and development are crucial for equipping employees with the knowledge and skills they need to work safely. Toolbox talks offer an effective way to deliver targeted training on specific safety topics, such as forklift safety, electrical safety, and working in confined spaces. By regularly discussing hazards and safe work procedures, employees gain a deeper understanding of the risks associated with their tasks and how to control them.

Toolbox talks also help identify gaps in knowledge, allowing for timely training that can prevent injuries and reduce risk. When employees are well-trained and safety topics are discussed openly, the entire workplace benefits from a stronger, more proactive approach to health and safety.

Emergency Preparedness and Response

Being prepared for emergencies is a vital part of any health and safety program. Toolbox talks provide an ideal platform to review emergency preparedness, including emergency procedures like evacuation routes, fire extinguisher locations, and first aid protocols. By discussing these topics and providing regular training, employees are better equipped to respond quickly and effectively if an emergency occurs.

This proactive approach helps prevent injuries, minimises damage, and ensures that everyone knows what to do in a crisis. Regularly reviewing emergency procedures through toolbox talks keeps safety at the forefront and reinforces the importance of being ready for any situation.

Suggested Toolbox Talk Topics

Rotating topics keeps talks relevant and prevents fatigue. Here are some ideas to cycle through:

- Working at heights and fall prevention.

- Manual handling and lifting techniques.

- PPE use and maintenance.

- Heat stress and hydration.

- Fatigue awareness and rest breaks.

- Site traffic and vehicle management.

- Electrical safety and lockout/tagout.

- Mental health and wellbeing.

- Hazard reporting and near misses.

- Emergency procedures and evacuation drills.

- Common injuries on site.

- Hazardous substances and chemical safety.

- Handling sharp objects safely.

- Fire extinguishers and fire safety.

- Working in a confined space.

- Identifying workplace hazards.

- Construction site safety.

- Preventing injury on construction sites.

A good practice is to maintain a toolbox talk calendar, scheduling topics that reflect site risks and seasonal changes.

Toolbox Talk Essentials at a Glance

| Step | Action | Why It Works |

| Choose a topic | Link to incidents, hazards, or seasonal risks. | Relevance keeps workers engaged. |

| Keep it short | 5–10 minutes, one theme only. | Attention stays focused. |

|

Use visuals/examples |

Real photos, equipment demos, stories. | Improves memory retention. |

| Ask questions | Encourage worker input and discussion to help identify issues that may affect their safety. | Builds ownership and participation. |

| Record attendance | Use Toolbox Talk Record Forms. | Demonstrates compliance and accountability. |

| Follow up | Address issues raised and report back, as this can positively affect the overall safety culture. | Builds trust and closes the loop. |

How SafetyDocs Supports Toolbox Talks

Preparing effective toolbox talks and keeping reliable records can be challenging without the right resources. That’s where SafetyDocs by SafetyCulture comes in. Businesses of all sizes can benefit from using SafetyDocs resources to improve their safety processes.

Our Toolbox Talk Templates, Record Forms, and Safety Checklists help supervisors:

- Save time by using pre-prepared templates that are easy to adapt to your site.

- Standardise safety talks across multiple crews and worksites.

- Document attendance and actions professionally, ensuring compliance with WHS requirements.

- Improve engagement with structured, practical topics ready to go.

Instead of scrambling for topics or creating forms from scratch, SafetyDocs provides everything you need to deliver toolbox talks that are consistent, relevant, and audit-ready. Download our ready-to-use Toolbox Talk Templates, Record Forms, and Safety Checklists today, perfect for making your next safety talk or pre-start safety meeting short, sharp, engaging, and compliant.

Author - Craig Cruickshank is the HSEQ Manager and Senior Technical Advisor at SafetyDocs by SafetyCulture.

Craig comes from a construction and environmental background, with experience in both the private and public sectors and is passionate about making health and safety information easy to find and understand for everyone.

Learn more about Craig's work on LinkedIn

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.

Share This Article